- Home

- About Journals

-

Information for Authors/ReviewersEditorial Policies

Publication Fee

Publication Cycle - Process Flowchart

Online Manuscript Submission and Tracking System

Publishing Ethics and Rectitude

Authorship

Author Benefits

Reviewer Guidelines

Guest Editor Guidelines

Peer Review Workflow

Quick Track Option

Copyediting Services

Bentham Open Membership

Bentham Open Advisory Board

Archiving Policies

Fabricating and Stating False Information

Post Publication Discussions and Corrections

Editorial Management

Advertise With Us

Funding Agencies

Rate List

Kudos

General FAQs

Special Fee Waivers and Discounts

- Contact

- Help

- About Us

- Search

The Ergonomics Open Journal

(Discontinued)

ISSN: 1875-9343 ― Volume 11, 2018

Physical Workload Assessment of Furniture Industry Workers by Using Owas Method

Kadir Özkaya1, Olcay Polat2, *, Velittin Kalinkara1

Abstract

Object:

Improper workplace design is one of the significant reasons for occupational accidents and injuries in labor-intensive production sites. Inadequate and incomplete working environments ignoring ergonomic factors at the planning level create persistent psychical disorders, increase mistakes and accident rates and decrease work productivity. Enhancement of the compliance between worker and task is a crucial step for improving productivity.

Method:

The worker can reach increased productivity with less physical load and less energy consumption when compliance is accomplished. This study has been implemented in a medium sized labor-intensive furniture factory located in Denizli, Turkey. In this study, physical workload of operators is the loading and unloadingby machinery in solid wood processing workshop of the factory. Initially, the working environment of this division is investigated ergonomically and then 12 of the machines are selected for implementation. Individual characteristics, working conditions and postures of the operators in the selected machines are determined by using surveys, measurements and video recording techniques. After analyzing loading and unloading operations of workers, operation times and posture frequencies are determined. Ovako Working Posture Analysis System (OWAS) is used to find the workloads and potential risk of work-related musculoskeletal disorders.

Result:

The results show that inadequate and incomplete working environment and operational designs are the main reasons for the high workload level and serious physical disorders among the workers. Operational design improvements related to working environment are presented to the senior management of the factory that may help decrease the risks of work-related musculoskeletal disorder in the workers.

Article Information

Identifiers and Pagination:

Year: 2018Volume: 11

First Page: 11

Last Page: 19

Publisher Id: TOERGJ-11-11

DOI: 10.2174/1875934301811010011

Article History:

Received Date: 30/04/2018Revision Received Date: 04/06/2018

Acceptance Date: 11/06/2018

Electronic publication date: 29/06/2018

Collection year: 2018

open-access license: This is an open access article distributed under the terms of the Creative Commons Attribution 4.0 International Public License (CC-BY 4.0), a copy of which is available at: (https://creativecommons.org/licenses/by/4.0/legalcode). This license permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

* Address correspondence to this authors at the Department of Industrial Engineering, Pamukkale University, 20160, Denizli, Turkey, Tel: +905064162900; Fax: +902582963262; E-mail: opolat@pau.edu.tr

| Open Peer Review Details | |||

|---|---|---|---|

| Manuscript submitted on 30-04-2018 |

Original Manuscript | Physical Workload Assessment of Furniture Industry Workers by Using Owas Method | |

1. INTRODUCTION

One of the most important reasons for occupational accidents and injuries in production systems is poorly designed working environment. Inadequate and incomplete working environment that ignores ergonomic factors at the planning stage, creates persistent psychical disorders, increases mistakes and accident rates and decreases work productivity. Improving productivity is the main goal of continuous improvement according to business managers. Enhancement of compliance between the worker and work is one of the efficient methods for the improvement of productivity.

Workers should not be overloaded in the working environment since they get tired when forced to work over their limited capacity [1Polat O, Mutlu Ö, Ozgormus E. A Mathematical Model for Assembly Line Balancing Problem Type 2 under Ergonomic Workload Constraint.Open Ergonomics J 2018. In Press:1-15.]. Fatigue can have negative impacts in terms of employees’ work efficiency, health, safety and psychological balance. Therefore, it is important to consider the performance limits of workers and determine the rest and working hours and improve working conditions in order to improve the productivity.

Incorrect work designs and awkward posture may cause loss of productivity and occupational health problems. On the other hand, working in a correct posture could have a positive impact on the total amount of work done as well as productivity. Many industries still require a significant amount of human labor despite the advancements in mechanization technologies [2Polat O, Kalayci CB. Ergonomic Risk Assessment of Workers in Garment Industry. Eight International Conference on Textile Science & Economy VIII May 16-21, 2016; 2016.2016.]. Working posture of workers could cause a decrease in productivity as well as an increase in work-related musculoskeletal disorders in the furniture industry, which is a labor-intensive sector [3Kalınkara V, Özkaya K, Polat O. Mobilya Sektörü Çalışanlarında Fiziksel Zorlanmanın Belirlenmesi. Mühendislik Bilimleri ve Tasarım Dergisi 2017; 5: 1-12.

[http://dx.doi.org/10.21923/jesd.82230] , 4Polat O, Mutlu Ö, Çakanel H, Doğan O, Özçetin E, Şen E. Bir Mobilya Fabrikasında Çalışan İşçilerin Çalışma Duruşlarının REBA Yöntemi ile Analizi. Mühendislik Bilimleri ve Tasarım Dergisi 2017; 5: 263-8.

[http://dx.doi.org/10.21923/jesd.41742] ]. Furniture production is ranked in the class of extremely hazardous occupations according to the Ministry of Labour and Social Security Regulations (July 2013,No: 28706, 13-07-2013). As a labor-intensive sector, many studies are conducted in different research areas of furniture industry, however, there are less studies related to ergonomics [5Jafry T, O’Neill DH. The application of ergonomics in rural development: a review. Appl Ergon 2000; 31(3): 263-8.

[http://dx.doi.org/10.1016/S0003-6870(99)00051-4] [PMID: 10855449] ]. Christensen, Pedersen [6Christensen H, Pedersen MB, Sjøgaard G. A national cross-sectional study in the Danish wood and furniture industry on working postures and manual materials handling. Ergonomics 1995; 38(4): 793-805.

[http://dx.doi.org/10.1080/00140139508925150] [PMID: 7729404] ] determined that the risk of neck injury is very high in furniture industry workers who work while their neck is in a forward position. Calvo [7Calvo A. Musculoskeletal disorders (MSD) risks in forestry: a case study to propose an analysis method. Agric Eng Int CIGR J 2009.] presented that 24% of furniture industry workers have back pain, 22% have muscular pain and 66% are exposed to repetitive jobs and/or vibrations. Difficult environmental conditions (low-high temperature, dusty environment, low lighting, steep and slippery etc)., heavy-duty (manual handling, bending and twisting), and dangerous tools such as saws, increase risks and cause work-related musculoskeletal disorders.

This study aims to investigate the risk levels caused by working postures and movements of furniture industry workers who specifically work in solid wood operations. To the best of our knowledge, this study is the first study that investigates workloads and risk assessment of work-related musculoskeletal disorders of furniture industry workers using OWAS methodology.

The study explained in detail in the next section aims to answer the following questions for a decision maker in a furniture industry:

- Which machines and operations carry the risks of developing occupational accidents and musculoskeletal disorders?

- How are working postures of workers changing in different machines and operations?

- Which working postures and their combinations are riskier for the musculoskeletal system

This paper is structured as follows. Section 2 introduces the methods for physical workload evaluation methods including OWAS. Section 3 includes findings of ergonomic risk assessment of a furniture factory. Finally, Section 4 concludes the paper and presents future research directions.

2. MATERIALS AND METHOD

This study investigates working postures of the workers who work in the solid wood workshop of a furniture factory in Denizli. As a preliminary study, the machines and operations in the solid wood processing workshop of the factory examined and 12 different machines that have excessive workloads and repetitive tasks have been selected for this investigation. Surveys regarding individual information and body measurements were prepared and conducted on 18 workers who operated these machines. The operations in these machines are categorized into three-module classes; loading module, which only executes material loading operations to machine, unloading module, and also loading module in which both the operations are executed by the same operator. Table 1 shows the work module categorization of machines according to related operations.

Work-related musculoskeletal disorders cause expensive health care problems that result in loss of income and productivity. It is known that risk assessment of physical workloads may help prevent the multiplication of disorders. Demand for repetitive activities, workplace and environmental conditions affect the measurement process of physical workloads [8Fallentin N, Kilbom Å, Viikari-Juntura E, Wærsted M, Eds. Evaluation of physical workload standards/guidelines from a Nordic perspective. Proceedings of the Human Factors and Ergonomics Society Annual Meeting 2000.

[http://dx.doi.org/10.1177/154193120004403508] ].

Common tools used to assess physical workload are JSI - the job strain index [9Moore JS, Garg A. The Strain Index: a proposed method to analyze jobs for risk of distal upper extremity disorders. Am Ind Hyg Assoc J 1995; 56(5): 443-58.

[http://dx.doi.org/10.1080/15428119591016863] [PMID: 7754975] ], NIOSH - the National Institute for Occupational Safety and Health lifting equation [10Waters TR, Putz-Anderson V, Garg A, Fine LJ. Revised NIOSH equation for the design and evaluation of manual lifting tasks. Ergonomics 1993; 36(7): 749-76.

[http://dx.doi.org/10.1080/00140139308967940] [PMID: 8339717] ], REBA - the rapid entire body assessment [11Hignett S, McAtamney L. Rapid entire body assessment (REBA). Appl Ergon 2000; 31(2): 201-5.

[http://dx.doi.org/10.1016/S0003-6870(99)00039-3] [PMID: 10711982] ], RULA - the rapid upper limp assessment [12McAtamney L, Nigel Corlett E. RULA: a survey method for the investigation of work-related upper limb disorders. Appl Ergon 1993; 24(2): 91-9.

[http://dx.doi.org/10.1016/0003-6870(93)90080-S] [PMID: 15676903] ]; MAC - the manual handling assessment charts [13Monnington S, Quarrie C, Pinder A, Morris L. Development of manual handling assessment charts (MAC) for health and safety inspectors 2003; 3-8.], OCRA - The concise exposure index [14Occhipinti E. OCRA: a concise index for the assessment of exposure to repetitive movements of the upper limbs. Ergonomics 1998; 41(9): 1290-311.

[http://dx.doi.org/10.1080/001401398186315] [PMID: 9754032] ], OWAS - Ovako Working posture Assessment. System [15Karhu O, Kansi P, Kuorinka I. Correcting working postures in industry: A practical method for analysis. Appl Ergon 1977; 8(4): 199-201.

[http://dx.doi.org/10.1016/0003-6870(77)90164-8] [PMID: 15677243] ] and QEC - Quick Exposure Check [16Li G, Buckle P. Current techniques for assessing physical exposure to work-related musculoskeletal risks, with emphasis on posture-based methods. Ergonomics 1999; 42(5): 674-95.

[http://dx.doi.org/10.1080/001401399185388] [PMID: 10327891] ]. See David [17David GC. Ergonomic methods for assessing exposure to risk factors for work-related musculoskeletal disorders. Occup Med (Lond) 2005; 55(3): 190-9.

[http://dx.doi.org/10.1093/occmed/kqi082] [PMID: 15857898] ] and Roman-Liu [18Roman-Liu D. Comparison of concepts in easy-to-use methods for MSD risk assessment. Appl Ergon 2014; 45(3): 420-7.

[http://dx.doi.org/10.1016/j.apergo.2013.05.010] [PMID: 23849897] ] for detailed comparison of common physical workload assessment tools.

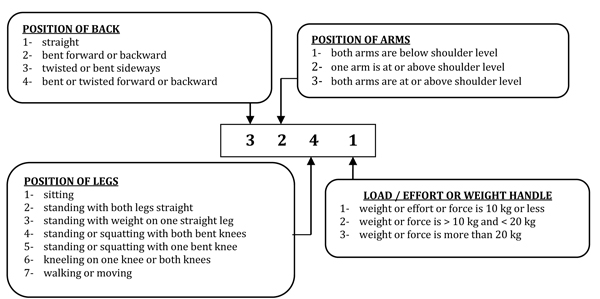

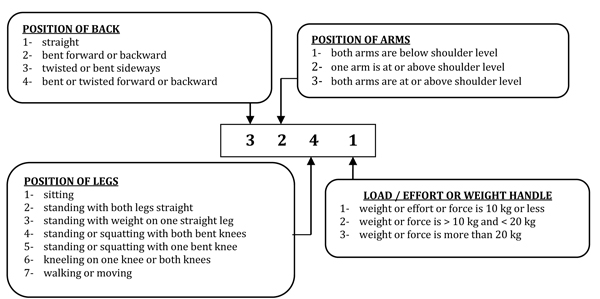

In this study, OWAS method that enables to analyze repetitive motions and various postures of workers has been used to investigate risk levels of various postures and movements. OWAS was developed by Karhu, Kansi [15Karhu O, Kansi P, Kuorinka I. Correcting working postures in industry: A practical method for analysis. Appl Ergon 1977; 8(4): 199-201.

[http://dx.doi.org/10.1016/0003-6870(77)90164-8] [PMID: 15677243] ] to identify and evaluate full body working postures. A posture is defined with the three digits code in the OWAS. The first digit defines the position of the back, the second digit defines the arms and the third digit defines the legs [19Keyserling WM. Postural analysis of the trunk and shoulders in simulated real time. Ergonomics 1986; 29(4): 569-83.

[http://dx.doi.org/10.1080/00140138608968292] [PMID: 3709510] ]. The later version of this method included a fourth digit that represents weight or use of force/effort [20Corlett EN. The evaluation of posture and its effects. In: Wilson JR, Corlett EN, editors. Evaluation of Human Work: A Practical Ergonomics Methodology. London: Taylor & Francis; 1995. p. 662-713.]. Fig. (1 ) describes OWAS coding system with alternative choices for each digit. In the related literature, various studies indicate that OWAS is one of the most reliable methods among different risk assessment methods [15Karhu O, Kansi P, Kuorinka I. Correcting working postures in industry: A practical method for analysis. Appl Ergon 1977; 8(4): 199-201.

) describes OWAS coding system with alternative choices for each digit. In the related literature, various studies indicate that OWAS is one of the most reliable methods among different risk assessment methods [15Karhu O, Kansi P, Kuorinka I. Correcting working postures in industry: A practical method for analysis. Appl Ergon 1977; 8(4): 199-201.

[http://dx.doi.org/10.1016/0003-6870(77)90164-8] [PMID: 15677243] , 21McAtamney L, Hignett S. REBA (rapid Entire Body Assesment) - More than a Postural Assesment Tool. In: Robertson SA, editor. Contemporary Ergonomics. London: Taylor & francis; 1997. p. 431-5.]. Therefore, OWAS method is selected to asses risks for operations in the solid wood processing workshop.

|

Fig. (1) Four-digit OWAS coding system for body parts [15Karhu O, Kansi P, Kuorinka I. Correcting working postures in industry: A practical method for analysis. Appl Ergon 1977; 8(4): 199-201. [http://dx.doi.org/10.1016/0003-6870(77)90164-8] [PMID: 15677243] , 22Rabiul Ahasan M, Väyrynen S, Kirvesoja H. Physical Workload Analysis Among Small Industry Activities Using Postural Data. Int J Occup Saf Ergon 1996; 2(1): 27-34. [http://dx.doi.org/10.1080/10803548.1996.11076334] [PMID: 10602575] ]. |

It is possible to analyze the risk level of each working posture and position combinations for the musculoskeletal system of workers with the help of OWAS methodology. In the OWAS method, four different risk categories are used to determine the priority of the risky postures. These are;

- Category 1: Working postures have no hazardous effects on the musculoskeletal system and no action is necessary.

- Category 2: Working postures have some hazardous effects on the musculoskeletal system and it is required to include ergonomic improvements in future plans.

- Category 3: Working postures have hazardous effects on the musculoskeletal system and it is necessary to make ergonomic improvements soon.

-

Category 4: Working postures have quite hazardous effects on the musculoskeletal system and it is urgent to make ergonomic improvements immediately [22Rabiul Ahasan M, Väyrynen S, Kirvesoja H. Physical Workload Analysis Among Small Industry Activities Using Postural Data. Int J Occup Saf Ergon 1996; 2(1): 27-34.

[http://dx.doi.org/10.1080/10803548.1996.11076334] [PMID: 10602575] ].

In order to investigate working postures of workers, operations performed by each worker are recorded with a video camera for 30 minutes. Then, the videos are investigated by 5 seconds intervals and working postures are determined by using a 4 digits system. The data are analyzed via using the WinOWAS software. Recommendations for actions graphs are created with the help of software and the graphs are assessed by a group of experts.

3. FINDINGS

Personal information and body measurements of participated workers in this study are given in Table 2.

Table 2 indicates that participated workers are active workforce and their age range is between 18 and 50. The Body Mass Indexes (BMI= “Weight (kg)”/ “Square of height (m)”) of the workers show that 61.1% of them are at normal weight, 27.8% of them are overweight and remaining 11.1% are obese. Survey results indicate that occupational accidents and musculoskeletal disorders commonly occur among overweight and obese workers. The majority of workers do not consider the solid wood workshop operations as “hard work”. However, lifting a load is identified as “hardest work” by the workers who have complaints.

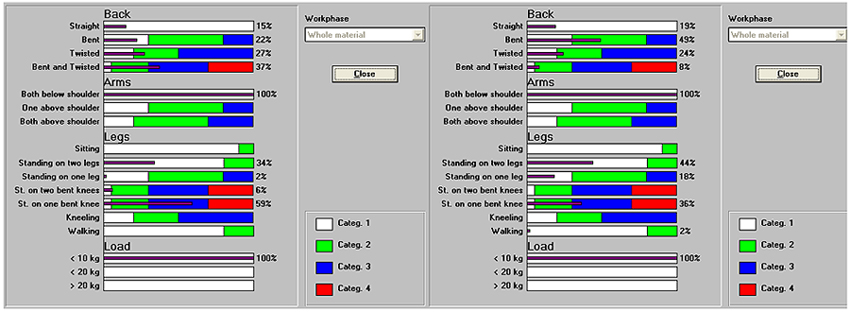

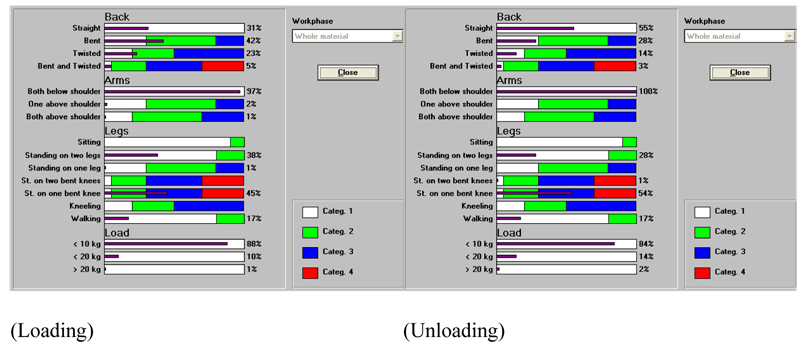

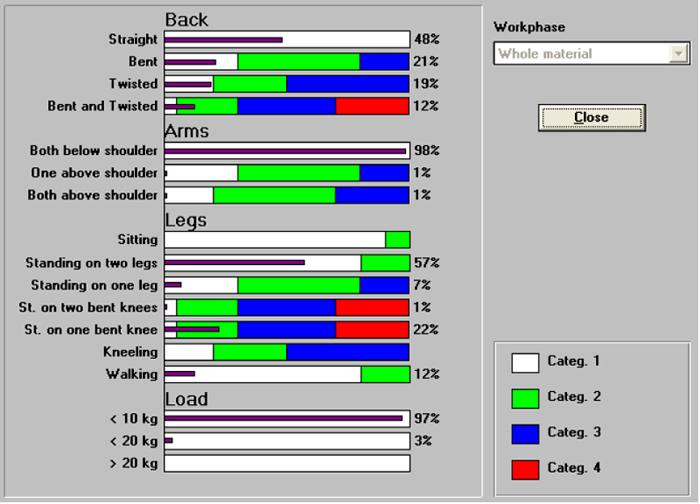

According to the result of OWAS analyses, there were no working postures in Category 4 which requires urgent ergonomic improvement actions. However, Category 3 postures which require ergonomic improvements soon are identified for machines 6, 7, 8, 9 and 10. While loading and unloading operations at machines 6 and 10 are executed by different workers, these operations were executed by the same worker at machines 7, 8 and 9. Fig. (2 ) shows recommendations for actions graphs for both operations at the machine 6 according to the OWAS analysis obtained from WinOWAS software.

) shows recommendations for actions graphs for both operations at the machine 6 according to the OWAS analysis obtained from WinOWAS software.

The graphs in Fig. (2 ) indicate that the back and leg positions in loading operations and the leg positions in unloading operations are at Category 3 risk level. The most common working postures in loading operations of this machine are “bent or twisted forward or backward position” (% 37) for the back and “standing or squatting with one bent knee position” (% 59) for the legs. The most common working posture in unloading operations is “standing or squatting with one bent knee” position (% 36) for the leg, which is at Category 3 risk level. Despite the usage of the lift tables with weight sensors in loading operations at machine 6, the high-risk level for the leg depends on the narrow working space and the wrong working position of the worker (Fig. 3

) indicate that the back and leg positions in loading operations and the leg positions in unloading operations are at Category 3 risk level. The most common working postures in loading operations of this machine are “bent or twisted forward or backward position” (% 37) for the back and “standing or squatting with one bent knee position” (% 59) for the legs. The most common working posture in unloading operations is “standing or squatting with one bent knee” position (% 36) for the leg, which is at Category 3 risk level. Despite the usage of the lift tables with weight sensors in loading operations at machine 6, the high-risk level for the leg depends on the narrow working space and the wrong working position of the worker (Fig. 3 ). The high feeding speed of the machine and the shorter length of workpieces cause repetitive motions which increase working speed of workers that result in awkward working postures.

). The high feeding speed of the machine and the shorter length of workpieces cause repetitive motions which increase working speed of workers that result in awkward working postures.

|

Fig. (2) Recommendations for actions graphs for M6 operations. |

|

Fig. (3) Working postures at M6 loading operations. |

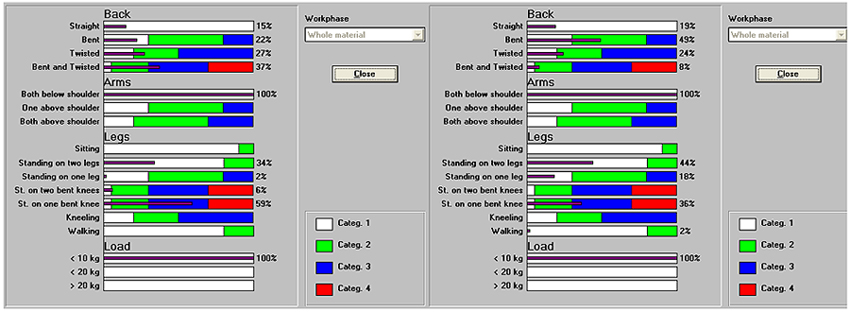

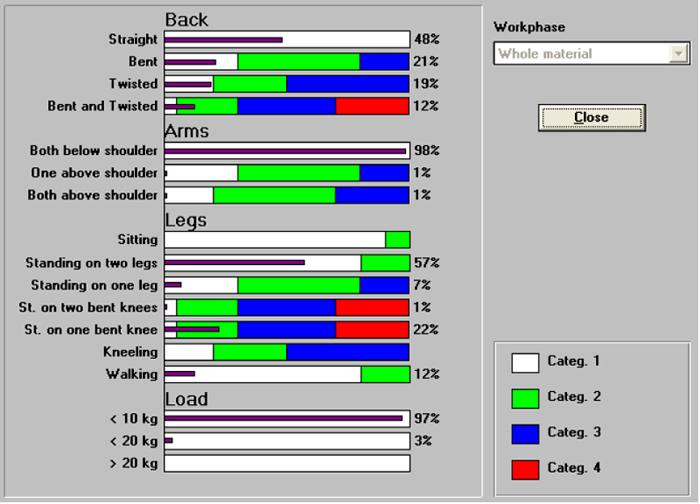

Fig. (4 ) shows recommendations for action graphs for both operations of M10 machine according to the OWAS analysis obtained by WinOWAS software.

) shows recommendations for action graphs for both operations of M10 machine according to the OWAS analysis obtained by WinOWAS software.

The graphs related to M10 machine indicate that “standing or squatting with one bent knee position” is the only position in Category 3 for both operations. The high-risk level in unloading operation is the result of the distance between the bench height and the stocking height (Fig. 5 ). This risk may be reduced by the usage of lift tables with weight sensors.

). This risk may be reduced by the usage of lift tables with weight sensors.

|

Fig. (4) Recommendations for actions graphs for M10 operations. |

|

Fig. (5) Working postures at M10. |

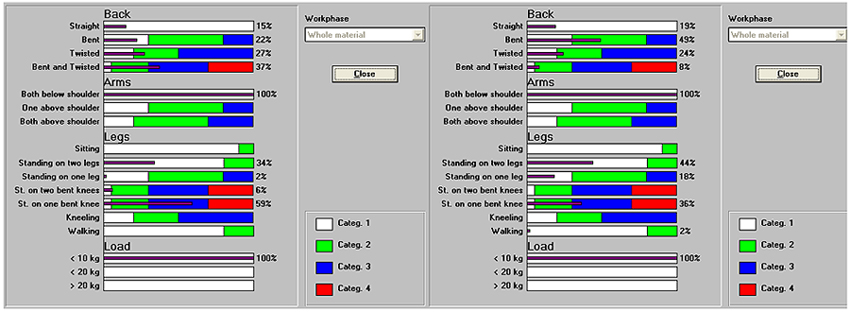

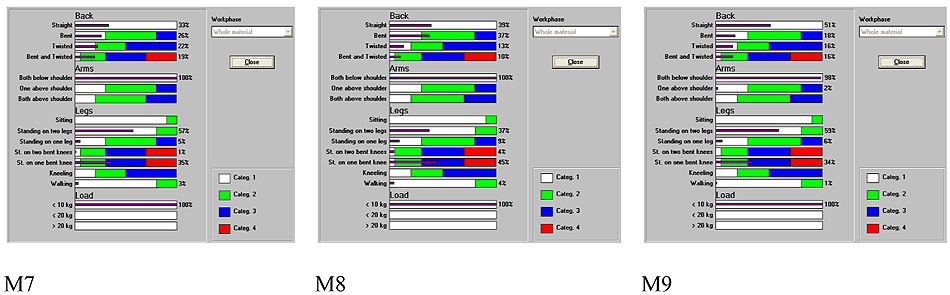

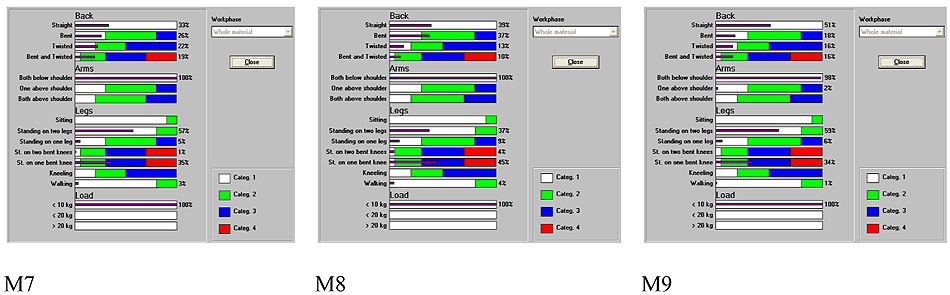

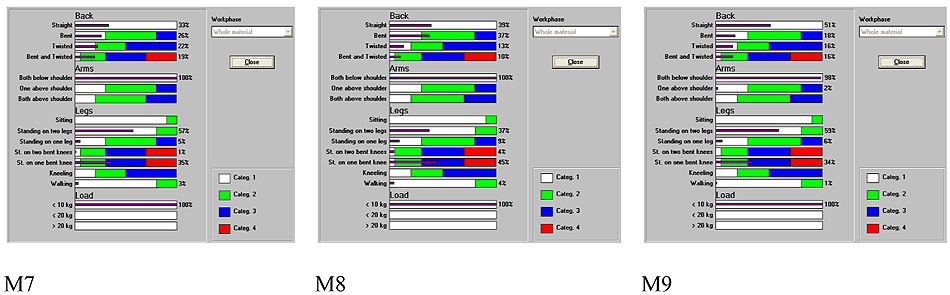

Fig. (6 ) shows recommendations for actions graphs for M7, M8 and M9 machines in which loading and unloading operations are executed by the same workers.

) shows recommendations for actions graphs for M7, M8 and M9 machines in which loading and unloading operations are executed by the same workers.

|

Fig. (6) Recommendations for actions graphs for M7, M8 and M9. |

The graphs in Fig. (6 ) show that there are risks for only the leg postures for all three machines. “Standing or squatting with one bent knee” position is seen in M7 at 35%, M8 at 45% and M9 at 34% which indicates Category 3 risk level.

) show that there are risks for only the leg postures for all three machines. “Standing or squatting with one bent knee” position is seen in M7 at 35%, M8 at 45% and M9 at 34% which indicates Category 3 risk level.

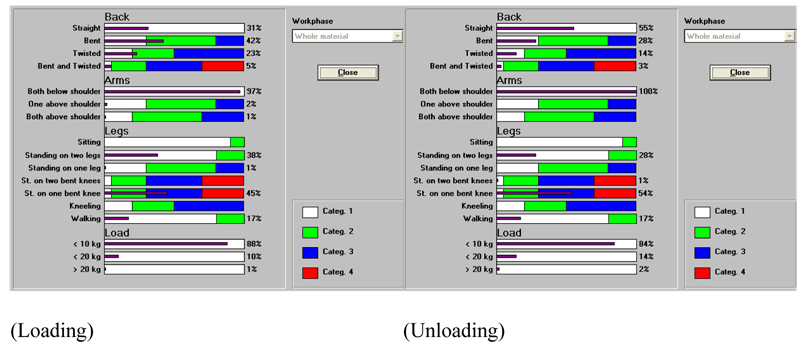

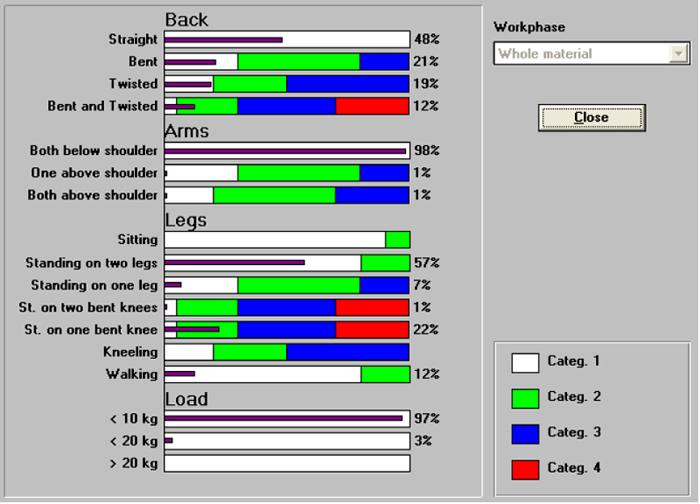

The overall results of OWAS analysis for the solid wood workshop that includes 18 workers are depicted in Fig. (7 ) obtained from WinOWAS software.

) obtained from WinOWAS software.

|

Fig. (7) Recommendations for actions graph for all solid wood operations. |

According to Fig. (7 ), there is no risky posture at Category 3 and 4 level out of all operations. The most common postures are “straight” for the back, “both arms are below shoulder level” position at arms, “standing with both legs straight position” for the legs while “weight or effort or force is 10 kg or less”. According to these results, it is possible to say that the posture positions do not overload the musculoskeletal system in solid work processing workshop. However, if we look at the machine/work and worker compatibility, there are considerable working posture problems in 5 of 12 machines investigated in the workshop.

), there is no risky posture at Category 3 and 4 level out of all operations. The most common postures are “straight” for the back, “both arms are below shoulder level” position at arms, “standing with both legs straight position” for the legs while “weight or effort or force is 10 kg or less”. According to these results, it is possible to say that the posture positions do not overload the musculoskeletal system in solid work processing workshop. However, if we look at the machine/work and worker compatibility, there are considerable working posture problems in 5 of 12 machines investigated in the workshop.

3. RESULTS

Excessive force requirements, adverse postural stresses, heavyweights, contact stresses, repetitive motions, vibration and temperature changes may lead to many ergonomic problems. In the content of this study, solid wood processing workshop of a large-scale furniture factory, which is a labor-intensive production system, is investigated to assess risks that lead to the working posture related musculoskeletal disorders. These disorders grow over time due to continued exposure to certain environmental factors or physical stresses. Therefore, 12 critical machines in this workshop are selected for the risk assessments. The results of the study show that 5 machines (Molding Machine, Circular Saw Machine, Sizing and Squaring Machine, Manuel Cross-Cut Sawing Machine and Band Saw) are in Category 3 risk level which is defined as “working postures have a hazardous effect on the musculoskeletal system and it is necessary to make ergonomic improvements soon”. The common feature of these machines is that they are low-technology and simple solid wood processing machinery used even in small-scale enterprises. Generally, incompatibility between workers and the benches and lifts heights, inadequate working space, and wrong working area design increase the risk levels of these machines. The elimination of these problems and new working area designs may provide an effective working environment for the workers, in which operations do not overload the musculoskeletal system of workers. The tasks in the furniture industry are often manual material handling operations that involve lifting heavy or bulky objects from the ground to the shoulder height and body twisting that causes employees to work at very high risk. In addition, exertion with the joints flexed, bending, pushing, and pulling loads, extended or rotated pinch grips are also often encountered with the low-technology machines. Not only each of these factors plays a critical role in disorders alone, but also when multiple factors are involved, an employee needs much longer recovery periods.

CONSENT FOR PUBLICATION

Not applicable.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGMENTS

Initial findings of this work were presented at the Second International Furniture Congress, October 13-15, 2016, Mugla, Turkey.

REFERENCES

| [1] | Polat O, Mutlu Ö, Ozgormus E. A Mathematical Model for Assembly Line Balancing Problem Type 2 under Ergonomic Workload Constraint.Open Ergonomics J 2018. In Press:1-15. |

| [2] | Polat O, Kalayci CB. Ergonomic Risk Assessment of Workers in Garment Industry. Eight International Conference on Textile Science & Economy VIII May 16-21, 2016; 2016.2016. |

| [3] | Kalınkara V, Özkaya K, Polat O. Mobilya Sektörü Çalışanlarında Fiziksel Zorlanmanın Belirlenmesi. Mühendislik Bilimleri ve Tasarım Dergisi 2017; 5: 1-12. [http://dx.doi.org/10.21923/jesd.82230] |

| [4] | Polat O, Mutlu Ö, Çakanel H, Doğan O, Özçetin E, Şen E. Bir Mobilya Fabrikasında Çalışan İşçilerin Çalışma Duruşlarının REBA Yöntemi ile Analizi. Mühendislik Bilimleri ve Tasarım Dergisi 2017; 5: 263-8. [http://dx.doi.org/10.21923/jesd.41742] |

| [5] | Jafry T, O’Neill DH. The application of ergonomics in rural development: a review. Appl Ergon 2000; 31(3): 263-8. [http://dx.doi.org/10.1016/S0003-6870(99)00051-4] [PMID: 10855449] |

| [6] | Christensen H, Pedersen MB, Sjøgaard G. A national cross-sectional study in the Danish wood and furniture industry on working postures and manual materials handling. Ergonomics 1995; 38(4): 793-805. [http://dx.doi.org/10.1080/00140139508925150] [PMID: 7729404] |

| [7] | Calvo A. Musculoskeletal disorders (MSD) risks in forestry: a case study to propose an analysis method. Agric Eng Int CIGR J 2009. |

| [8] | Fallentin N, Kilbom Å, Viikari-Juntura E, Wærsted M, Eds. Evaluation of physical workload standards/guidelines from a Nordic perspective. Proceedings of the Human Factors and Ergonomics Society Annual Meeting 2000. [http://dx.doi.org/10.1177/154193120004403508] |

| [9] | Moore JS, Garg A. The Strain Index: a proposed method to analyze jobs for risk of distal upper extremity disorders. Am Ind Hyg Assoc J 1995; 56(5): 443-58. [http://dx.doi.org/10.1080/15428119591016863] [PMID: 7754975] |

| [10] | Waters TR, Putz-Anderson V, Garg A, Fine LJ. Revised NIOSH equation for the design and evaluation of manual lifting tasks. Ergonomics 1993; 36(7): 749-76. [http://dx.doi.org/10.1080/00140139308967940] [PMID: 8339717] |

| [11] | Hignett S, McAtamney L. Rapid entire body assessment (REBA). Appl Ergon 2000; 31(2): 201-5. [http://dx.doi.org/10.1016/S0003-6870(99)00039-3] [PMID: 10711982] |

| [12] | McAtamney L, Nigel Corlett E. RULA: a survey method for the investigation of work-related upper limb disorders. Appl Ergon 1993; 24(2): 91-9. [http://dx.doi.org/10.1016/0003-6870(93)90080-S] [PMID: 15676903] |

| [13] | Monnington S, Quarrie C, Pinder A, Morris L. Development of manual handling assessment charts (MAC) for health and safety inspectors 2003; 3-8. |

| [14] | Occhipinti E. OCRA: a concise index for the assessment of exposure to repetitive movements of the upper limbs. Ergonomics 1998; 41(9): 1290-311. [http://dx.doi.org/10.1080/001401398186315] [PMID: 9754032] |

| [15] | Karhu O, Kansi P, Kuorinka I. Correcting working postures in industry: A practical method for analysis. Appl Ergon 1977; 8(4): 199-201. [http://dx.doi.org/10.1016/0003-6870(77)90164-8] [PMID: 15677243] |

| [16] | Li G, Buckle P. Current techniques for assessing physical exposure to work-related musculoskeletal risks, with emphasis on posture-based methods. Ergonomics 1999; 42(5): 674-95. [http://dx.doi.org/10.1080/001401399185388] [PMID: 10327891] |

| [17] | David GC. Ergonomic methods for assessing exposure to risk factors for work-related musculoskeletal disorders. Occup Med (Lond) 2005; 55(3): 190-9. [http://dx.doi.org/10.1093/occmed/kqi082] [PMID: 15857898] |

| [18] | Roman-Liu D. Comparison of concepts in easy-to-use methods for MSD risk assessment. Appl Ergon 2014; 45(3): 420-7. [http://dx.doi.org/10.1016/j.apergo.2013.05.010] [PMID: 23849897] |

| [19] | Keyserling WM. Postural analysis of the trunk and shoulders in simulated real time. Ergonomics 1986; 29(4): 569-83. [http://dx.doi.org/10.1080/00140138608968292] [PMID: 3709510] |

| [20] | Corlett EN. The evaluation of posture and its effects. In: Wilson JR, Corlett EN, editors. Evaluation of Human Work: A Practical Ergonomics Methodology. London: Taylor & Francis; 1995. p. 662-713. |

| [21] | McAtamney L, Hignett S. REBA (rapid Entire Body Assesment) - More than a Postural Assesment Tool. In: Robertson SA, editor. Contemporary Ergonomics. London: Taylor & francis; 1997. p. 431-5. |

| [22] | Rabiul Ahasan M, Väyrynen S, Kirvesoja H. Physical Workload Analysis Among Small Industry Activities Using Postural Data. Int J Occup Saf Ergon 1996; 2(1): 27-34. [http://dx.doi.org/10.1080/10803548.1996.11076334] [PMID: 10602575] |