| Modification |

Figure |

Justifications |

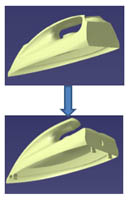

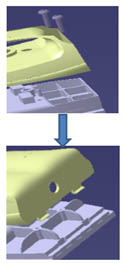

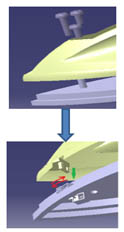

| Modify the casing by adding a hanger and tow snaps |

|

The two screws can be eliminated as it can be replaced with a tow-snap. The hanger can be assembled to the sole plate cover. |

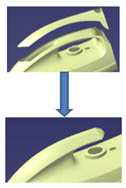

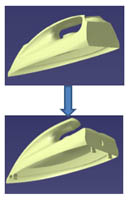

| Eliminate the handle (combined with casing) |

|

The handle can be combined with casing as a single component. There is no reason to divide these components |

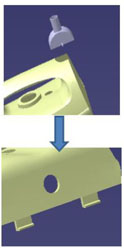

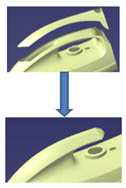

| Eliminate the vertical cord lift (combined with casing) |

|

For the casing design, by adding a hole at the back of the casing will allow the movement of the cord. It will reduce the assembly time and also cost saving. |

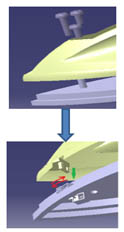

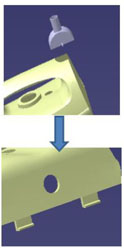

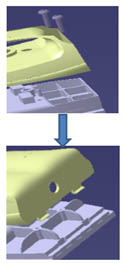

| Add a slide button at a sole plate cover. |

|

Adding a slide button on the sole plate cover for ease of releasing or attaching of the casing. This method requires less time for the installation and screws are unneeded. |

| Eliminate two threads and two screws |

|

These threads can be replaced by two snap holes, which are matched to the casing during installation. This design does not need the use a screwdriver during installation and it helps to save assembly time and indirectly increased the design efficiency of the product. |