- Home

- About Journals

-

Information for Authors/ReviewersEditorial Policies

Publication Fee

Publication Cycle - Process Flowchart

Online Manuscript Submission and Tracking System

Publishing Ethics and Rectitude

Authorship

Author Benefits

Reviewer Guidelines

Guest Editor Guidelines

Peer Review Workflow

Quick Track Option

Copyediting Services

Bentham Open Membership

Bentham Open Advisory Board

Archiving Policies

Fabricating and Stating False Information

Post Publication Discussions and Corrections

Editorial Management

Advertise With Us

Funding Agencies

Rate List

Kudos

General FAQs

Special Fee Waivers and Discounts

- Contact

- Help

- About Us

- Search

The Open Food Science Journal

(Discontinued)

ISSN: 1874-2564 ― Volume 13, 2021

Construction and Validation of an Online Subcritical Adsorption-based Device for Assisting CO2 Recycling during a Supercritical Fluid Extraction Process

R. Abel C. Torres, Diego T. Santos, M. Angela A. Meireles*

Abstract

Background:

An efficient process for extracting food ingredients from plant materials should demand the use of a reduced volume of extraction solvent to obtain a final product that is free of solvent and reduces both the processing time and the costs. In some cases, achieving a new efficient process requires the modification, reconfiguration or renewal of elements that are part of a processing unit.

Objective:

The goal of this work is to describe the development of a modification of a commercial supercritical fluid extraction pilot unit designed to assist CO2 recycling based on subcritical adsorption on an adsorbent material. In addition to the construction and validation of the system, a cost survey was performed to estimate the cost of the homemade device developed to allow effective CO2 recycling.

Methods:

The developed device was tested using cotton and Celite® as model adsorption materials and annatto seeds (Bixa orellana L.) as a model plant material. A 0.65 L adsorption column was installed with a set of connections and valves that complemented the unit’s recycle system. The validation procedure consisted of defatting annatto seeds.

Results:

The proposed online subcritical adsorption-based device was technically validated using cotton as an adsorbent material. The cost survey showed that an estimated total cost of USD 5731.36 would be required to install the developed device in a Supercritical Fluid Extraction (SFE) unit similar to the one coupled here (5 L).

Conclusion:

The proposed device was demonstrated to be very promising for application in the pseudocontinuous SFE, recirculating the same amount of CO2 mass exceeding the S/F values by 14 times, when compared to a process without a CO2 recycling system.

Article Information

Identifiers and Pagination:

Year: 2018Volume: 10

First Page: 46

Last Page: 61

Publisher Id: TOFSJ-10-46

DOI: 10.2174/1874256401810010046

Article History:

Received Date: 14/8/2018Revision Received Date: 16/10/2018

Acceptance Date: 12/11/2018

Electronic publication date: 31/12/2018

Collection year: 2018

open-access license: This is an open access article distributed under the terms of the Creative Commons Attribution 4.0 International Public License (CC-BY 4.0), a copy of which is available at: (https://creativecommons.org/licenses/by/4.0/legalcode). This license permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

* Address correspondence to this author at the LASEFI/DEA/FEA (School of Food Engineering)/UNICAMP (University of Campinas), CEP 13083-862, Campinas, SP, Brazil; Tel: +55 19 35210100; E-mail: maameireles@lasefi.com

| Open Peer Review Details | |||

|---|---|---|---|

| Manuscript submitted on 14-8-2018 |

Original Manuscript | Construction and Validation of an Online Subcritical Adsorption-based Device for Assisting CO2 Recycling during a Supercritical Fluid Extraction Process | |

1. INTRODUCTION

Several substances that can confer or intensify color, such as carotenoids (β-carotene, lycopene, lutein and zeaxanthin) [1Martin A, Mattea F, Gutierrez L, Miguel F, Cocero MJ. Co-precipitation of carotenoids and bio-polymers with the supercritical anti-solvent process. J Supercrit Fluids 2007; 41(1): 138-47.

[http://dx.doi.org/10.1016/j.supflu.2006.08.009] , 2Tocchini L, Mercadante AZ. Extração e determinação, por clae, de bixina e norbixina em coloríficos. Food Sci Technol (Campinas) 2001; 21: 310-3.

[http://dx.doi.org/10.1590/S0101-20612001000300010] ], are added to foods to confer an extensive range of colors, including shades of red, orange and yellow [3Stahl W, Sies H. Antioxidant activity of carotenoids. Mol Aspects Med 2003; 24(6): 345-51.

[http://dx.doi.org/10.1016/S0098-2997(03)00030-X] [PMID: 14585305] ]. There is a growing interest in using natural pigments because they present a wide range of biological activities, including antioxidant, anti-inflammatory, and anticancer activity [4Santos DT, Albarelli JQ, Beppu MM, Meireles MAA. Stabilization of anthocyanin extract from jabuticaba skins by encapsulation using supercritical CO2 as solvent. Food Res Int 2013; 50(2): 617-24.

[http://dx.doi.org/10.1016/j.foodres.2011.04.019] -6Tapiero H, Townsend DM, Tew KD. The role of carotenoids in the prevention of human pathologies. Biomed Pharmacother 2004; 58(2): 100-10.

[http://dx.doi.org/10.1016/j.biopha.2003.12.006] [PMID: 14992791] ].

Annatto seeds contain several carotenoid derivatives (including bixin and norbixin), terpenoids, tocotrienols, aromatic hydrocarbons, and flavonoids [7Rodrigues SM, Soares VLF, de Oliveira TM, Gesteira AS, Otoni WC, Costa MGC. Isolation and purification of RNA from tissues rich in polyphenols, polysaccharides, and pigments of annatto (Bixa orellana L.). Mol Biotechnol 2007; 37(3): 220-4.

[http://dx.doi.org/10.1007/s12033-007-0070-9] [PMID: 17952668] ]. According to Rosa et al. [8Rosa MTMG, Silva EK, Santos DT, Petenate AJ, Meireles MAA. Obtaining annatto seed oil miniemulsions by ultrasonication using aqueous extract from Brazilian ginseng roots as a biosurfactant. J Food Eng 2016; 168: 68-78.

[http://dx.doi.org/10.1016/j.jfoodeng.2015.07.024] ], annatto seed oil is rich in tocotrienols, especially γ- and δ-tocotrienols.

To obtain these compounds from annatto seeds, some conventional extraction techniques have been studied, such as extraction in oil, alkaline aqueous solutions and organic solvents [9van Scheppingen WB, Boogers IALA, Duchateau ALL. Study on decomposition products of norbixin during bleaching with hydrogen peroxide and a peroxidase by means of UPLC-UV and mass spectrometry. Food Chem 2012; 132(3): 1354-9.

[http://dx.doi.org/10.1016/j.foodchem.2011.11.118] [PMID: 29243622] ] and mechanical extraction [10Barrozo MAS, Santos KG, Cunha FG. Mechanical extraction of natural dye extract from Bixa orellana seeds in spouted bed. Ind Crops Prod 2013; 45: 279-82.

[http://dx.doi.org/10.1016/j.indcrop.2012.12.052] ].

However, applications whose processes are called clean extraction technologies have also been studied. For example, Supercritical Fluid Extraction (SFE) has been studied by Albuquerque & Meireles [11Albuquerque CLC, Meireles MAA. Defatting of annatto seeds using supercritical carbon dioxide as a pretreatment for the production of bixin: Experimental, modeling and economic evaluation of the process. J Supercrit Fluids 2012; 66: 86-95.

[http://dx.doi.org/10.1016/j.supflu.2012.01.004] ], Moraes et al. [12Moraes MN, Zabot GL, Meireles MAA. Applications of supercritical fluids in latin america: Past, present and future trends. Food Public Health 2014; 4(3): 162-79.

[http://dx.doi.org/10.5923/j.fph.20140403.11] ] and Johner & Meireles [13Johner JCF, Meireles MAA. Construction of a supercritical fluid extraction (SFE) equipment: validation using annatto and fennel and extract analysis by thin layer chromatography coupled to image. Food Sci Technol (Campinas) 2016; 36(2): 210-47.

[http://dx.doi.org/10.1590/1678-457X.0027] ]; pressurized liquid extraction (PLE) has been studied by Rodrigues et al. [14Rodrigues LM, Alcázar-Alay SC, Petenate AJ, Meireles MAA. Bixin extraction from defatted annatto seeds. C R Chim 2014; 17(3): 268-83.

[http://dx.doi.org/10.1016/j.crci.2013.10.010] ]; and Supercritical Fluid Extraction of Emulsions (SFEE) and Supercritical Antisolvent Precipitation (SAS) have been studied by Mattea et al. [15Mattea F, Martín Á, Matías-Gago A, Cocero MJ. Supercritical antisolvent precipitation from an emulsion: β-Carotene nanoparticle formation. J Supercrit Fluids 2009; 51(2): 238-47.

[http://dx.doi.org/10.1016/j.supflu.2009.08.013] ] and Santos & Meireles [16Santos DT, Meireles MAA. Micronization and encapsulation of functional pigments using supercritical carbon dioxide. J Food Process Eng 2013; 36(1): 36-49.

[http://dx.doi.org/10.1111/j.1745-4530.2011.00651.x] ], respectively.

Based on clean extraction technologies, an efficient process for extracting food ingredients from plant materials should require the use of a small volume of extraction solvent to obtain the product without the presence of the solvent in the extract, reducing both the processing time and production costs. At the same time, efficient extraction contributes to the reduction of CO2 emissions, which represents an international concern [17Nong D, Siriwardana M. Environmental and economic impacts of a joint emissions trading scheme. Int J Glob Energy Issues 2017; 40(3-4): 184-206.

[http://dx.doi.org/10.1504/IJGEI.2017.086619] ], as well as the search to reduce CO2 emissions in relation to the energy generated to achieve such a reduction [18Royer-Adnot J, Le Gallo Y. Economic analysis of combined geothermal and CO2 storage for small-size emitters. Energy Procedia 2017; 114: 7118-25.

[http://dx.doi.org/10.1016/j.egypro.2017.03.1853] ]. In Brazil and Latin America, the extraction of bioactive compounds from vegetable matrices using CO2 as a solvent represents an attractive field [12Moraes MN, Zabot GL, Meireles MAA. Applications of supercritical fluids in latin america: Past, present and future trends. Food Public Health 2014; 4(3): 162-79.

[http://dx.doi.org/10.5923/j.fph.20140403.11] ]. As far as is known, semi-industrial commercial units are provided with a recycling mechanism for CO2 that is sometimes reported to have some limitations in terms of functionality, since part of the extract goes to the reservoir of the recycling system, which limits its permanent use. One reason for this limitation is the high CO2 flow rate that causes an inefficient separation. Decreasing CO2 flow rate can be a possible solution. However, it consequently increases the extraction duration. Another possible solution is employing an adsorption column. Achieving new and efficient adsorption processes requires, in some cases, the modification, reconfiguration or renewal of the elements that are part of the processing unit. Therefore, the present work is related to these adaptations and details the modification of a commercial supercritical fluid extraction pilot unit to assist CO2 recycling based on subcritical adsorption on an adsorbent material. Cotton and Celite® 512 medium were used as model adsorption materials, and annatto seeds (Bixa orellana L.) were used as a model plant material. In this context, this study aims to describe the development of a modification of a commercial supercritical fluid extraction pilot unit designed to assist CO2 recycling based on subcritical adsorption on an adsorbent material. In addition to process construction and validation, a cost survey was performed to estimate the cost of the homemade device developed to allow effective CO2 recycling.

2. MATERIALS AND METHODS

2.1. Raw Material Characterization

Annatto seeds of the variety Piave (Bixa orellana L.) were donated by Urucum do Brasil Ltda, located in Santa Marta, Monte Castelo - SP, Brazil. The seeds were stored at 291 K in a freezer (VF55D, Metalfrio, São Paulo, Brazil). The mean diameter of the annatto seeds, 3.82 ± 0.09 mm, was calculated by an adaptation of Silva et al. [19Silva GF, Gamarra FMC, Oliveira AL, Cabral FA. Extraction of bixin from annatto seeds using supercritical carbon dioxide. Braz J Chem Eng 2008; 25: 419-26.

[http://dx.doi.org/10.1590/S0104-66322008000200019] ]. A total of 30 annatto seeds were removed from 3.5 kg of seeds for the measurement of the lengths of their axes. Then, to repeat the measurement of lengths, 30 seeds were placed back into the bag (which again weighed 3.5 kg), and after homogenization, the procedure was repeated.

The moisture content of the annatto seeds, 11.61 ± 0.02 g/100 g, was analyzed as described by AOAC [20AOAC. Official Methods of Analysis of AOAC International 1997.] and was determined in triplicate by drying at 378 K until reaching constant mass. The true density (1.35 ± 0.01 g/cm3) of the particles was measured by pycnometry with helium gas at the Central Analytical Laboratory of the Institute of Chemistry - UNICAMP (Campinas, Brazil). The apparent density (0.7609 ± 0.0000 g/cm3) in SFE bench-scale unit, of the bed was calculated by dividing the sample feed mass by the extractor volume. The porosity of the bed was calculated by equation 1.

|

(1) |

where ρr is the true density of the particles; ρa is the apparent density of the bed; and ε: is the porosity of the bed.

2.2. Description of Supercritical Fluid Extraction Units

Two commercial supercritical fluid extraction units were used in this study, a bench-scale unit and a pilot-scale unit. In the bench-scale unit, the extraction kinetics of annatto seeds was investigated. However, in the pilot-scale unit, several elements were changed and adapted to test the possibility of recycling CO2 without creating drag or with the least amount of drag, which would prevent the CO2 from entering the extraction column.

2.2.1. SFE Bench-scale Unit

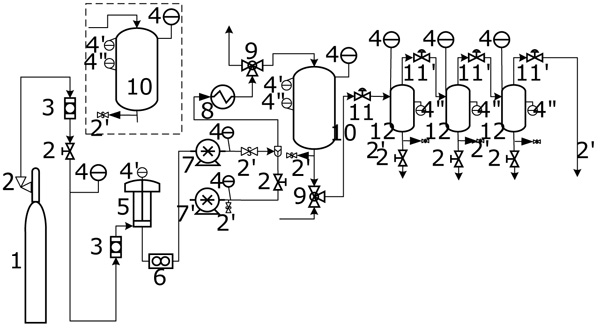

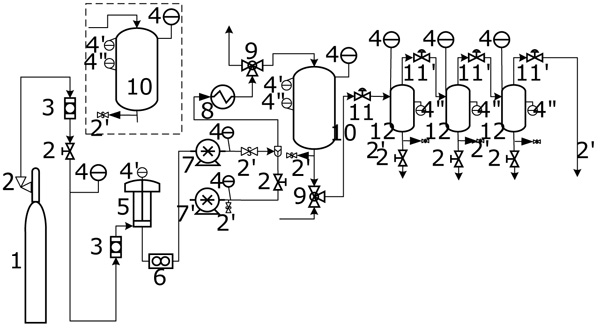

The main elements that compose the commercial SFE bench-scale unit (Spe-ed model, Applied Separations, Allentown, USA) are represented in Fig. (1 ). The extraction column used in this study has a total volume of 25 mL, height of 83.5 mm, and diameter of 20.0 mm.

). The extraction column used in this study has a total volume of 25 mL, height of 83.5 mm, and diameter of 20.0 mm.

The operational sequence was as follows: CO2 was cooled at 263 K by a cooling bath (Logen Scientific, LS-540, Diadema, Brazil) before reaching the pump. The desired temperature for CO2 was obtained using hot air circulation by blow motor and blow motor resistor inside the oven module, which included the extraction column and the pipes connected to the inlet and outlet of the column. Accordingly, CO2 transited a thermodynamic phase change from liquid state to supercritical state. Then, the extractor was kept at 20 MPa and 313 K for 20 min (static time) to get saturation of the solvent in the extractor before solvent pumping. After that, the outlet valve of extractor was opened, and the dynamic time of extraction was started. The extract was collected in a 100 mL glass vial immersed in an ice bath at ambient pressure. The total CO2 was measured with a flow totalizer (Itrón, model G1.0, Campinas, Brazil), and the mass flow for each process was calculated in an Excel spreadsheet, weighting the values of the density of the CO2 found elsewhere [21 NIST. National Institute of Standards and Technology. 2017. Available at: http://www.nist.gov] keeping the environment at a constant temperature; CO2 was not recirculated. After the extraction, the glass vial was placed in a desiccator for thirty minutes to guarantee the complete elimination of CO2.

2.2.2. SFE Pilot-scale Unit Description

The commercial SFE pilot-scale unit (Thar Technologies, model SFE-2X5 LF-2-FMC, Pittsburgh, USA) used in this study was acquired in the framework of the PITE/FAPESP project (05/60948-1) in partnership with the company CENTROFLORA (Botucatu, SP) during the period 2006-2009.

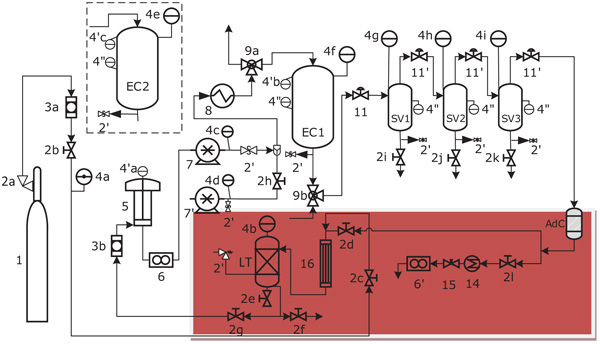

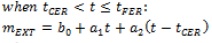

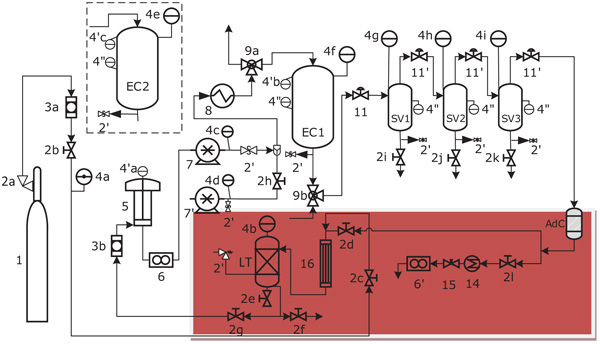

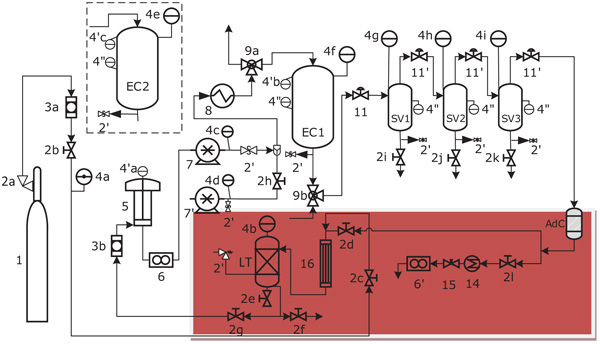

The main elements that compose the initial state of the commercial SFE pilot-scale unit are represented in Fig. (2 ). The extraction column used in this study has a total volume of 5 L, height of 620 mm, and diameter of 106 mm. The open-closure sealing system is an internal thread with a depth of 7 threads x 39.0 mm and the cover is the external thread with a depth of 6 threads x 36.0 mm and sealing gasket (the maximum operating pressure and temperature are 68.95 MPa and 363 K, respectively).

). The extraction column used in this study has a total volume of 5 L, height of 620 mm, and diameter of 106 mm. The open-closure sealing system is an internal thread with a depth of 7 threads x 39.0 mm and the cover is the external thread with a depth of 6 threads x 36.0 mm and sealing gasket (the maximum operating pressure and temperature are 68.95 MPa and 363 K, respectively).

The operational sequence was as follows: CO2 passed through the heat exchanger with coiled tube where it was cooled at 263 K by a cooling bath (Polyscience recirculator 6100T, Niles, Illinois, USA) and for the mass flow meter (Siemens Coriolis flowmeters SITRANS F C MASS 2100 Di 1.5), before reaching the pump (maximum flowrate of 350 mL/min, maximum operating pressure of 34.47 MPa). Then CO2 passed through a heat exchanger, which raised the temperature and entered into the extraction column equipped with an electric heating jacket (Ogden Mighty-Miser CBE06A12A-02212, 2000 W, 240 V) kept to 313 K and 20 MPa for 20 min (static time) to get saturation of the solvent in the extractor before solvent pumping. After that, outlet three-way valve of extractor and the automated backpressure valve were opened, and the dynamic time of extraction was started. The extract was collected in three separators (Cyclone type, volume of 1 L, diameter of 74 mm, height of 275 mm. Each one with an electric heating jacket, Ogden Mighty-Miser CBE04J04A-02158, 500 W, 240 V). The total CO2 was measured with a flow totalizer (Itrón, model G1.6, Campinas, Brazil), and the mass flow for each process was calculated in an Excel spreadsheet, weighting the values of the density of the CO2 found elsewhere [21 NIST. National Institute of Standards and Technology. 2017. Available at: http://www.nist.gov] keeping the environment at a constant temperature. CO2 was recirculated in 4 of 5 experiments (B, C, D and E). After the extraction, the extract was collected in glass bottles of 100 mL and placed in a desiccator for thirty minutes to guarantee the complete elimination of CO2.

2.3. Supercritical Fluid Extraction Experiments

2.3.1. SFE Bench-scale Unit Experiments

CO2 was used as the solvent (99.9% CO2, Gama Gases Especiais Ltd, São Bernardo do Campo, Brazil) The global extraction yield (X0) was obtained from kinetic curve data corresponding to the diffusion-controlled period [22Zabot GL, Moraes MN, Petenate AJ, Meireles MAA. Influence of the bed geometry on the kinetics of the extraction of clove bud oil with supercritical CO2. J Supercrit Fluids 2014; 93: 56-66.

[http://dx.doi.org/10.1016/j.supflu.2013.10.001] ]. The selected extraction conditions used in this study (313 K and 20 MPa) were set based on a previously optimized method for the recovery of tocotrienol-rich oil from annatto seeds by SFE developed by Albuquerque & Meireles [11Albuquerque CLC, Meireles MAA. Defatting of annatto seeds using supercritical carbon dioxide as a pretreatment for the production of bixin: Experimental, modeling and economic evaluation of the process. J Supercrit Fluids 2012; 66: 86-95.

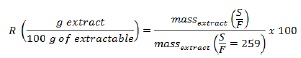

[http://dx.doi.org/10.1016/j.supflu.2012.01.004] ] in an SFE bench-scale unit (290 mL). A 25 mL extractor was filled thoroughly with annatto seeds (15.4689 ± 0.0001 g (d.b.), the CO2 flow rate (11.10 ± 0.04 g/min) was kept constant. After that, the extraction bed was filled, and a plug of glass wool was placed on both the lower and upper ends of the extraction column. The relative yield (R, g extract/100 g of extractable) for the extraction was calculated using equation 2:

|

(2) |

In our study, the global extraction yield (X0) was determined by the summation of the extract obtained from ethanol cleaning (after evaporation of the solvent) [23Prado JM. Estudo do aumento de escala do processo de extração supercrítica em leito fixo. Ph.D thesis, University of Campinas/School of Food Engineering, Campinas, Brazil, 2010.] and the extract obtained during the extraction kinetics experiment. Then, the glass vials were stored at 255 K until analysis. The X0 data obtained in this unit were compared with the data obtained in the pilot-scale unit.

The experimental overall extraction curve (OEC) data obtained using the bench unit were adjusted to fit a spline with three straight lines using the software SAS 9.2®. This software allowed the annatto oil extraction kinetic parameters to be determined, including the constant extraction rate (CER) period (tCER), the mass transfer rate for the CER period (MCER), the yield for the CER period (RCER), the mass ratio of solute in the fluid phase at the extractor outlet for the CER period (YCER), the falling extraction rate (FER) period (tFER), the mass transfer rate for the FER period (MFER), the yield for the FER period (RFER) and the mass ratio of solute in the fluid phase at the extractor outlet for the FER period (YFER).

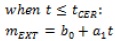

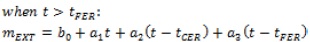

Jesus et al. [24Jesus SP, Calheiros MN, Hense H, Meireles MAA. A simplified model to describe the kinetic behavior of supercritical fluid extraction from a rice bran oil byproduct. Food Public Health 2013; 3: 215-22.

[http://dx.doi.org/10.5923/j.fph.20130304.05] ] describe the spline model adopted in this study with three periods using extraction kinetics data:

|

(3) |

|

(4) |

|

(5) |

where t is the time of extraction (min); mEXT is the mass of extract (g); b0 is the linear coefficient (zero-order term) of the CER straight line (g); and a1, a2 and a3 are the slope coefficients (first-order terms) of the CER, FER, and DC (diffusion-controlled) straight lines, respectively (g/min).

According to the results of Meireles [25Meireles MAA. Extraction of bioactive compounds from latim american plants.Supercritical Fluid Extraction of Nutraceuticals and Bioactive Compounds: CRC Press - Taylor & Francis Group, LLC 2008; 243-74.] and Moraes et al. [26Moraes MN, Zabot GL, Meireles MAA. Extraction of tocotrienols from annatto seeds by a pseudo continuously operated SFE process integrated with low-pressure solvent extraction for bixin production. J Supercrit Fluids 2015; 96: 262-71.

[http://dx.doi.org/10.1016/j.supflu.2014.09.007] ], tCER is the intersection of the first straight line with the second, and tFER is the intersection of the second straight line with the third (DC, diffusion-controlled) straight line.

Noticeably, this model is exclusively used for extractor, and it does not cover the adsorption column.

2.3.2. SFE Pilot-scale Unit Experiments

The extraction conditions (313 K and 20 MPa) set for the bench-scale unit for defatting annatto seeds were set for the SFE pilot-scale unit for 5 experimental runs. Based on previous studies performed in a pilot-scale unit, the automated backpressure valve was opened to flow CO2 with the mass flow rate of 200 g/min [23Prado JM. Estudo do aumento de escala do processo de extração supercrítica em leito fixo. Ph.D thesis, University of Campinas/School of Food Engineering, Campinas, Brazil, 2010.]. The fractionation of the extracts by pressure and temperature reduction was also performed to obtain the heaviest fraction in the first separation vessel (SV), and the lighter fractions in the following separator vessels were as follows: SV1 (P = 8.0 MPa, T = 313 K), SV2 (P = 6.5 MPa, T = 303 K) and SV3 (P = 6.5 MPa, T = 313 K). These data were defined through detailed literature review. The use of a higher pressure reduces the cost of recompressing the solvent for recycling within the process [27Takeuchi TM, Leal PF, Favareto R, et al. Study of the phase equilibrium formed inside the flash tank used at the separation step of a supercritical fluid extraction unit. J Supercrit Fluids 2008; 43(3): 447-59.

[http://dx.doi.org/10.1016/j.supflu.2007.08.002] ]. Thus, Prado [23Prado JM. Estudo do aumento de escala do processo de extração supercrítica em leito fixo. Ph.D thesis, University of Campinas/School of Food Engineering, Campinas, Brazil, 2010.] inferred that a pressure of approximately 6 MPa may be economically interesting for use in separator vessels at an industrial level. Therefore, in this study, we chose to set the pressure of the last separator vessel (SV3) at 6.5 MPa.

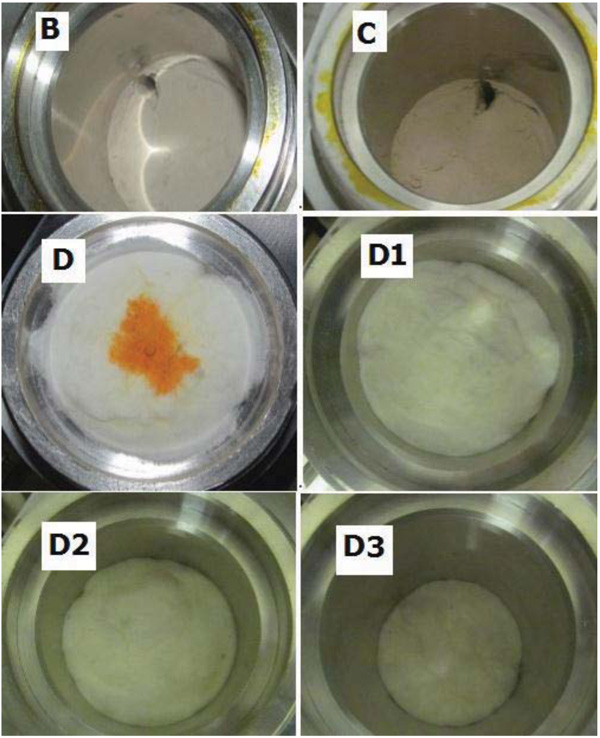

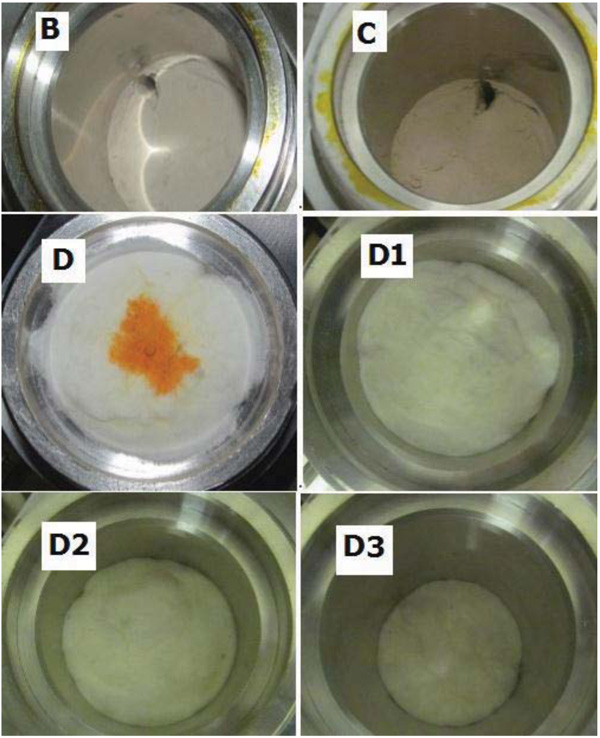

There were 5 experimental runs carried out in the SFE pilot-scale unit. Experimental run A was developed according to the initial state just as the pilot-scale unit was found (in other words without any modification). The recycling and adsorption system was adapted to the pilot-scale unit to carry out the experimental runs from B to E. In the experimental runs, B and C, and, D and E, silicon dioxide (Celite® 512 medium) and cotton (in a uniform orthopedic blanket roll) (Hydrophilic Cotton, Medi House, São Paulo, Brazil), respectively, were tested as adsorbent materials for the validation of the developed online subcritical adsorption-based device for assisting CO2 recycling during SFE. When using the Celite® 512 medium, the 0.65 L adsorption column was filled with 150 g of silicon dioxide inserted to the bottom part of the AdC, and a plain weave stainless steel disc filter (wire diameter 0.18 mm, aperture size 0.15 mm) was inserted on the top of silicon dioxide. The remaining part of AdC was filled with 0.43 kg of glass beads with a diameter of 0.3 mm, but when using cotton, only 100 g filled the adsorption column.

The tendency of the effect of three moments of pressurization/depressurization was studied in the experimental runs B and C, in that a single moment of pressurization/depressurization was applied for the experimental runs D and E.

2.4. Description of SFE Pilot-scale Modifications

To recirculate CO2 at purity conditions similar to those of the initial feed, an AdC was installed between the SV3 outlet and the CO2 condenser, which was connected to what is here called the lung tank (LT). The capacity of LT is 15 L volume, having a maximum allowable working pressure of 10.34 MPa at 298 K, and it is made of 304 stainless steel.

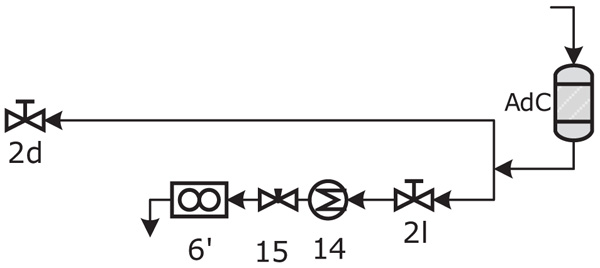

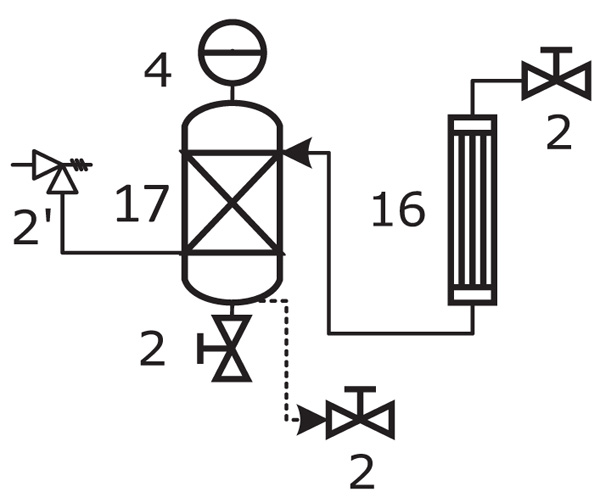

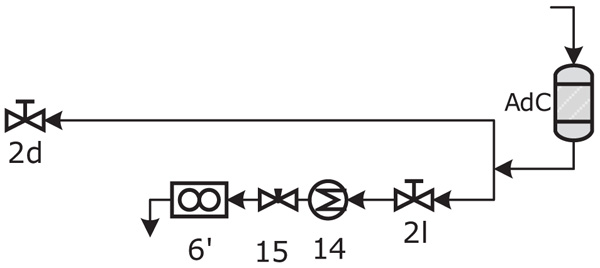

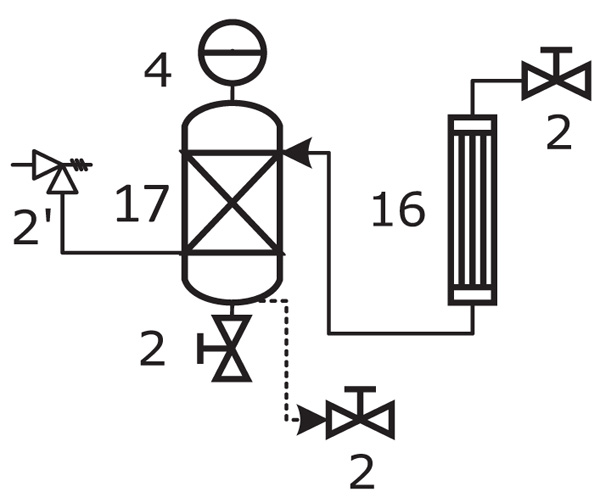

Fig. (3 ) shows the initial step of the recycle system construction, as well as its main components.

) shows the initial step of the recycle system construction, as well as its main components.

|

Fig. (3) Initial step of the recycle system construction. (2) blocking valve, (2’) safety valve, (4) manometer, (16) shell and tube heat exchanger, (17) lung tank (LT). |

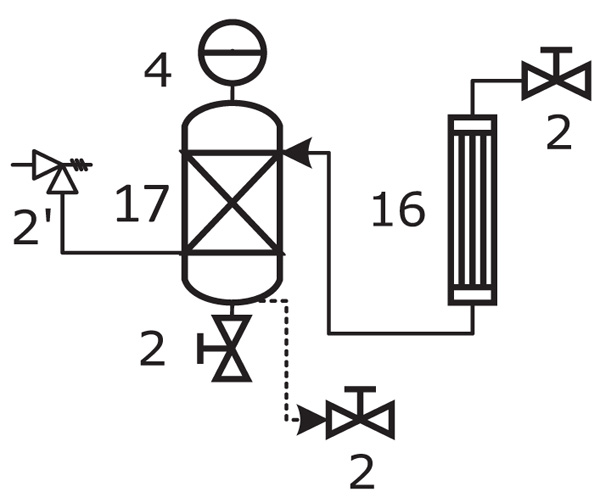

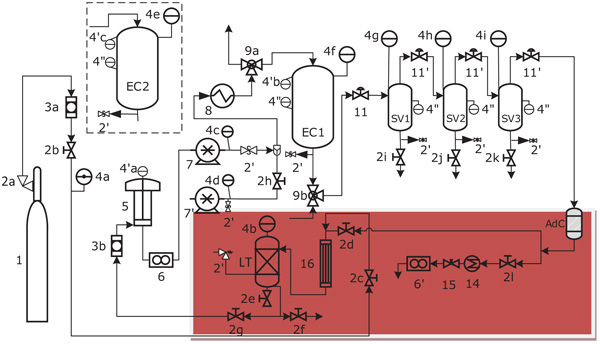

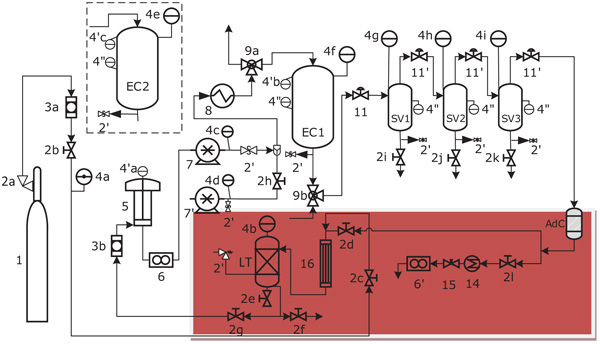

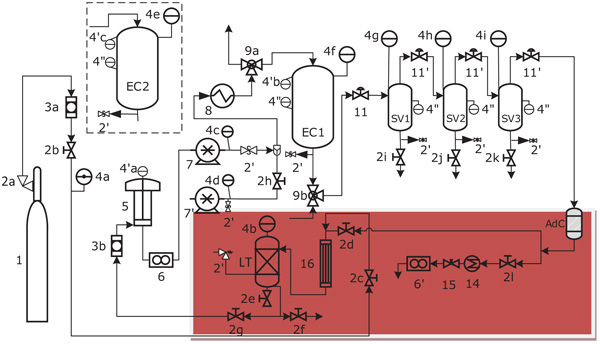

The purpose of installing an AdC (this column was maintained at an average room temperature of 295 K, it has no heating system) as part of the initial CO2 recycle system was to keep the CO2 mass in the same condition as if it were entering the system for the first time (i.e., 99.9% purity). To this end, a 0.65 L (height of 22 cm and diameter of 12 cm) AdC was installed with a set of connections and valves that complemented the pilot-scale unit’s recycle system. Fig. (4 ) shows the sequence of connections, valves, and piping that was installed in the final stage of the study, and Fig. (5

) shows the sequence of connections, valves, and piping that was installed in the final stage of the study, and Fig. (5 ) shows the final state of the SFE pilot-scale unit after the inclusion of the online subcritical adsorption-based device (shown in red).

) shows the final state of the SFE pilot-scale unit after the inclusion of the online subcritical adsorption-based device (shown in red).

To facilitate cleaning and to understand in detail the parts that composed the developed recycle device, all the connections were disassembled to evaluate the possibility of avoiding dragging the extract toward the LT (17, in Fig. (3 )). The blocking valve located at the inlet of the refrigeration heat exchanger (CO2 condensing column) can operate at up to 41.37 MPa CWP (cold working pressure) and 311 K. The shell and tube heat exchanger used for refrigeration was of model # 00256-06 (Garden City, NY, USA), and the tube side pressure could withstand maximum conditions of 8.3 MPa [28 EXERGY-LLC. Model # 00256-06, Shell & Tube Heat Exchanger. USA, 17/05/2017 2017. Available at: http://heat-exchangers. exergyllc.com/item/shell-tube-heat-exchangers/35-series-shell-tube-heat- exchangers/ 00256-06]. The shell and tube heat exchanger contains 61 numbers of tubes with length and diameter of 51 cm, and 2.5 mm respectively. The cooling solution, composed of water + ethylene glycol (50:50 v/v), entered the side of the heat exchanger by applying pressure to the inner pipes of the exchanger. According to PolyScience [29 POLYSCIENCE. Chillers and Coolers. USA, 2017. Available at: https://polyscience.com/products/chillers/benchtop], the maximum pressure exerted by the recirculating cooling bath (PolyScience recirculator 6100T - 230 V / 60 Hz / 12.2 A / 1 HP, Niles, Illinois, USA) that drives the refrigerant solution is 0.62 MPa. In addition, the minimum range of the flow rate alarm set point is 3 to 8 LPM (liters per minute), and the maximum flow rate at 0 MPa is 13.2 LPM [30POLYSCIENCE. User Guide - Refrigerated Recirculating Chillers 2016; 51.].

)). The blocking valve located at the inlet of the refrigeration heat exchanger (CO2 condensing column) can operate at up to 41.37 MPa CWP (cold working pressure) and 311 K. The shell and tube heat exchanger used for refrigeration was of model # 00256-06 (Garden City, NY, USA), and the tube side pressure could withstand maximum conditions of 8.3 MPa [28 EXERGY-LLC. Model # 00256-06, Shell & Tube Heat Exchanger. USA, 17/05/2017 2017. Available at: http://heat-exchangers. exergyllc.com/item/shell-tube-heat-exchangers/35-series-shell-tube-heat- exchangers/ 00256-06]. The shell and tube heat exchanger contains 61 numbers of tubes with length and diameter of 51 cm, and 2.5 mm respectively. The cooling solution, composed of water + ethylene glycol (50:50 v/v), entered the side of the heat exchanger by applying pressure to the inner pipes of the exchanger. According to PolyScience [29 POLYSCIENCE. Chillers and Coolers. USA, 2017. Available at: https://polyscience.com/products/chillers/benchtop], the maximum pressure exerted by the recirculating cooling bath (PolyScience recirculator 6100T - 230 V / 60 Hz / 12.2 A / 1 HP, Niles, Illinois, USA) that drives the refrigerant solution is 0.62 MPa. In addition, the minimum range of the flow rate alarm set point is 3 to 8 LPM (liters per minute), and the maximum flow rate at 0 MPa is 13.2 LPM [30POLYSCIENCE. User Guide - Refrigerated Recirculating Chillers 2016; 51.].

With the modifications made in the recycling system, the experiments from B to E were developed as follows: the processes B and C are as follows: 1) The extractor was pressurized from 0.1 MPa to 20 MPa during 20 min. Then, the extractor remains in this condition for 20 min (static time). After that, the extractor was depressurized to 7 MPa. 2) The extractor was pressurized again from 7 MPa to 20 MPa during 10 min and remained in this condition for 20 min (static time). Then, the output valve of extractor was opened to start the dynamic extraction until reaching values of S/F ratio (g CO2/g annatto) 25, for B, and 10.36, for C. Next, the recycling valve (2d in Fig. (5 )) was closed, and the ambient valve (2l in Fig. (5

)) was closed, and the ambient valve (2l in Fig. (5 )) was opened to flow out the CO2 to the ambient. After that, the extract was collected and weighted. 3) The same procedure of part 2 was repeated except that the pressurization occurs from 0.1 MPa to 20 MPa during 20 min.

)) was opened to flow out the CO2 to the ambient. After that, the extract was collected and weighted. 3) The same procedure of part 2 was repeated except that the pressurization occurs from 0.1 MPa to 20 MPa during 20 min.

In cases D and E, first the extractor was pressurized from 0.1 MPa to 20 MPa during 20 min. Then, the extractor remains in this condition for 20 min (static time). After that, the output valve of extractor was opened to start the dynamic extraction until reaching values of S/F 25.45, for D, and 55.98, for E. Next, the recycling valve (2d in Fig. (5 )) was closed, and the ambient valve (2l in Fig. (5

)) was closed, and the ambient valve (2l in Fig. (5 )) was opened to flow out the CO2 to the ambient.

)) was opened to flow out the CO2 to the ambient.

3. RESULTS AND DISCUSSION

3.1. Effects of the Ratio of Solvent Mass to Feed Mass on the Extraction Yield Using the SFE Bench-scale Unit

The global extraction yield (X0) was obtained from kinetic curves corresponding to the diffusion-controlled period. In practical aspects, the global extraction yield (X0) represents the maximum amount of extract that can be recovered from a raw material at a given extraction pressure and temperature. In contrast to the bench-scale unit, in the pilot-scale unit, it is not possible to collect extracts continuously during kinetics experiments. It is necessary to interrupt the solvent flow and then depressurize the separators while keeping the extractor pressurized so that the extract can be collected, as is the case with experimental runs B and C. After this procedure, the extraction can be resumed until the next collection point. Interrupting the extraction at each point implies intermediary static periods in the extractor. Thus, in this study, we used the bench-scale unit to determine the overall extraction curve (OEC) and X0 for annatto-seed extraction.

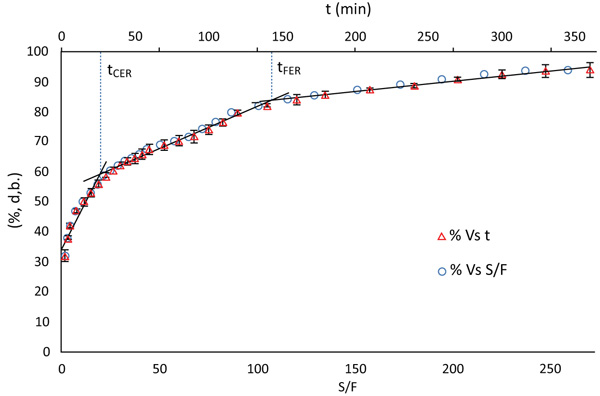

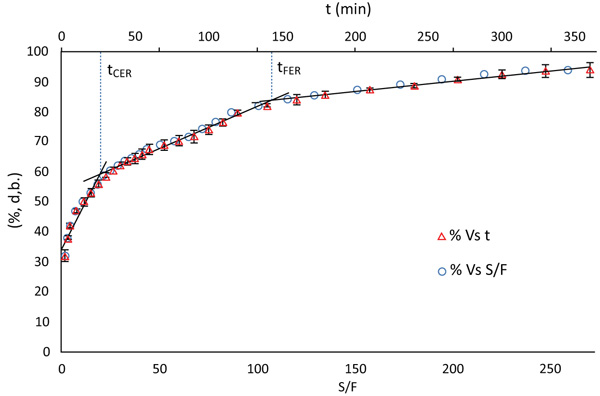

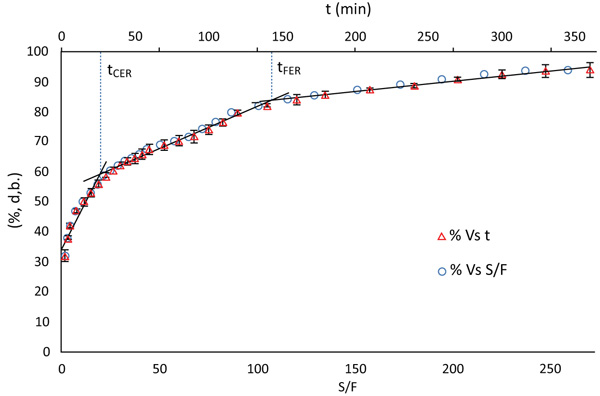

Fig. (6 ) shows the OEC obtained for annatto-seed SFE at the bench scale. The results are expressed in terms of the relative yield (R, g extract/100 g of extractable) of the extraction. The term extractable represents the maximum amount of extract that can be recovered from a raw material at a given extraction pressure and temperature within the diffusion-controlled period (S/F ratio of 259 g CO2/g annatto, which is in a good agreement with the value obtained by Moraes et al. [26Moraes MN, Zabot GL, Meireles MAA. Extraction of tocotrienols from annatto seeds by a pseudo continuously operated SFE process integrated with low-pressure solvent extraction for bixin production. J Supercrit Fluids 2015; 96: 262-71.

) shows the OEC obtained for annatto-seed SFE at the bench scale. The results are expressed in terms of the relative yield (R, g extract/100 g of extractable) of the extraction. The term extractable represents the maximum amount of extract that can be recovered from a raw material at a given extraction pressure and temperature within the diffusion-controlled period (S/F ratio of 259 g CO2/g annatto, which is in a good agreement with the value obtained by Moraes et al. [26Moraes MN, Zabot GL, Meireles MAA. Extraction of tocotrienols from annatto seeds by a pseudo continuously operated SFE process integrated with low-pressure solvent extraction for bixin production. J Supercrit Fluids 2015; 96: 262-71.

[http://dx.doi.org/10.1016/j.supflu.2014.09.007] ]). The OEC presents a short CER (constant extraction rate) period of 26.17 min, which accounts for almost 60% of the total extract. A DC (diffusion controlled) period follows, with a rapid decrease in the extraction rate; this is the intermediary FER (falling extraction rate) period. The kinetic parameters calculated from the analysis performed using the software SAS 9.2® are in Table 1, where tCER is the time of the CER, MCER is the mass-transfer rate and RCER is the yield achieved during this period. The value of tCER roughly represents the minimum time an SFE cycle should last to keep the process economically viable [25Meireles MAA. Extraction of bioactive compounds from latim american plants.Supercritical Fluid Extraction of Nutraceuticals and Bioactive Compounds: CRC Press - Taylor & Francis Group, LLC 2008; 243-74.]. YCER is the mass ratio of solute in the supercritical phase at the bed outlet during the CER period.

|

Fig. (6) Overall Extraction Curve (OEC) for annatto-seed extraction (313 K and 20 MPa) in the bench-scale unit; (__) indicates data fitted using SAS 9.2®. |

Obtaining the CO2 density as a function of ambient pressure (from [21 NIST. National Institute of Standards and Technology. 2017. Available at: http://www.nist.gov]) together with the monitoring of both ambient pressure (measured through an aneroid barometer) and the volumetric flow of CO2 (measured with the flow totalizer -16 of Fig. (1 ) and with a chronometer), allowed us to control CO2 mass flow rate as accurate as possible. Accordingly, the error for CO2 flow rate, 0.04 g/min, compared to the average of CO2 flow rate, 11.10 g/min, indicates the infinitesimal impact of the precision of CO2 flow rate on both the overall extraction curves and model parameters in this study.

) and with a chronometer), allowed us to control CO2 mass flow rate as accurate as possible. Accordingly, the error for CO2 flow rate, 0.04 g/min, compared to the average of CO2 flow rate, 11.10 g/min, indicates the infinitesimal impact of the precision of CO2 flow rate on both the overall extraction curves and model parameters in this study.

Based on the OEC and kinetic parameters calculated, we also performed 3 runs in the SFE bench-scale system to ensure the reliability of experimental data using different solvent mass to feed mass (S/F) ratios which can be seen in Fig. (6 ). The Table 2 shows the results for the global extraction yield (X0) and residual extract indicators when S/F was varied. It can be observed that both the S/F ratio and the global extraction yield (X0) values had a coefficient of variation close to 1%, which represents a high reliability in the performed process. The Standard deviation reported in this table are related to the uncertainty of the experiments.

). The Table 2 shows the results for the global extraction yield (X0) and residual extract indicators when S/F was varied. It can be observed that both the S/F ratio and the global extraction yield (X0) values had a coefficient of variation close to 1%, which represents a high reliability in the performed process. The Standard deviation reported in this table are related to the uncertainty of the experiments.

On the other hand, the process had a high variability with respect to the values obtained related to the extract collected during the cleaning of the unit (residual extract amount), which can be seen in terms of the standard deviation and coefficient of variation, indicating a strong correlation to the S/F ratio. The lower the S/F ratio is, the lower is the X0 and the higher is the accumulation of extract inside the parts of the SFE bench-scale unit, and vice versa. In contrast, approximately 6% of the total amount of extract that can be extracted from the annatto seeds using the SFE conditions used here (313 K and 20 MPa) corresponds to the amount of extract lost from the retention of extract in the pieces of equipment used. The residence time of CO2 in the extractor of bench unit was 0.08 s, while the residence time of pilot unit was from 8.03 to 19.60.

Santos et al. [31Santos DT, Albuquerque CLC, Meireles MAA. Procedia Food Sci 2011; 1: 1581-8.

[http://dx.doi.org/10.1016/j.profoo.2011.09.234] ], using the same commercial equipment, observed a similar percentage of residual extract (7%) for annatto-seed extraction under different SFE conditions (31 MPa, 333 K). The authors also compared commercial equipment with a homemade system that had a similar volume capacity and observed that a significantly higher amount of residual extract was deposited in the tubing line when the homemade equipment was used compared with the amount of residual extract obtained using the commercial SFE apparatus; thus, when using the homemade modification that we applied to the pilot-scale unit, accounting for this loss of extract was a concern.

Before studying the effects of the ratio of solvent mass to feed mass on the extraction yield using the SFE pilot-scale unit, we performed preliminary tests with the developed online subcritical adsorption-based device coupled to the system to validate the device. Silicon dioxide (Celite® 512 medium) and cotton (in a uniform orthopedic blanket roll) (Hydrophilic Cotton, Medi House, São Paulo, Brazil) were tested as adsorbent materials. The technical viability validation criterion adopted, in addition to visual observation of the adsorbent material after the SFE process, consisted of monitoring the effects of the increased solvent mass to feed mass (S/F) ratio on the extraction yield and percentage of residual extract in the equipment parts and comparing the results for the SFE pilot-scale unit coupled with the online subcritical adsorption-based device with the results for the SFE bench-scale unit.

3.2. Preliminary Tests of the Developed Online Subcritical Adsorption-based Device for Assisting CO2 Recycling in an SFE Pilot-scale Unit

Table 3 shows the results for extraction yield and residual extract percentage when solvent mass to feed mass ratio (S/F) was varied. The term extraction yield is defined as the summation of mass of extract obtained in three separators per 100 g of raw material. Moreover, the term residual extract percentage in this table indicates the amount of residual extract retained inside the tubing system of the SFE unit. Based on this table, the Extraction yield was increased from 2.84, for B, to 3.09, for C. The residual extract was decreased from 8.12, for B, to 6.55, for C. The main reason for this drop of residual extract is the higher value of S/F for C compared to B that leads higher removal of extract available in the tube lines and connections. It can be observed that the values obtained related to the extract collected during the cleaning of the unit (residual extract percentage) presented a strong correlation to the values of S/F ratio.

The higher the S/F ratio, the higher the extraction yield (measured by collecting the extracts in the 3 separation vessels), and the lower the accumulation of extract inside the parts of the SFE pilot scale unit (Residual Extract Percentage %). So, the use of silicon dioxide as adsorbent material for increasing extract recovery besides allow CO2 recycling is an important issue to be addressed.

The two adsorbent materials tested were compared in terms of operational aspects and cost. Because cotton is a soft-textured fibrous material, it facilitated the operability of the adsorption column at the time of packaging and unpacking. Almost 100 g (with a cost equivalent to approximately R$ 25.00/kg, which is very cheap - approximately 10% of the cost of silicon dioxide (Celite® 512 medium, R$ 263.00/kg)) was adequate to fill the 0.65 L volume of the adsorption column. In addition, other operational limitations (i.e., the formation of preferred paths, as well as the loss of mass between the internal spaces of the adsorption column covers when collecting the Celite® 512 medium at the end of processing), made this product less preferable compared with cotton.

Another important conclusion regarding the operability of the proposed supercritical fluid extraction process concerned the cleaning step.

The need to reduce these cleaning times and the amount of cleaning solvents required led to the identification of empty spaces (Fig. 8 ) where the extracted material accumulated after each processing run. Studies performed by Torres [32Torres RADC. Purificação de partículas de bixina por precipitação com CO2 supercrítico como antissolvente a partir de solução de ativos obtida da extração de sementes semi desengorduradas de urucum (Bixa orellana L.) assistida por ultrassom. Master thesis, University of Campinas/School of Food Engineering, Campinas, Brazil, 2015.] showed a similarity to this case, and therefore, the same strategies, such as the use of Teflon bushings, were applied to improve the equipment. Using Teflon bushings in the separators caused a dramatic drop in both cleaning time, from 40 h (after each experimental run, especially in cases of A. B and C) to 12 h (after each experimental run, D and E), and consumption solvent (essentially ethanol) volumes, from 14 L to 3 L.

) where the extracted material accumulated after each processing run. Studies performed by Torres [32Torres RADC. Purificação de partículas de bixina por precipitação com CO2 supercrítico como antissolvente a partir de solução de ativos obtida da extração de sementes semi desengorduradas de urucum (Bixa orellana L.) assistida por ultrassom. Master thesis, University of Campinas/School of Food Engineering, Campinas, Brazil, 2015.] showed a similarity to this case, and therefore, the same strategies, such as the use of Teflon bushings, were applied to improve the equipment. Using Teflon bushings in the separators caused a dramatic drop in both cleaning time, from 40 h (after each experimental run, especially in cases of A. B and C) to 12 h (after each experimental run, D and E), and consumption solvent (essentially ethanol) volumes, from 14 L to 3 L.

|

Fig. (8) Teflon bushings used to avoid the accumulation of extract in the SFE pilot-scale unit coupled with the developed online subcritical adsorption-based device. |

3.3. Effects of the Ratio of Solvent Mass to Feed Mass on the Extraction Yield Using the SFE Pilot-scale Unit Coupled with the Online Subcritical Adsorption-based Device

After unit adjustments and the technical viability demonstration of the inclusion of the subcritical adsorption-based device in the SFE pilot-scale unit, 5 experimental runs (A-E) were performed to evaluate the effect of the solvent mass to feed mass (S/F) ratio on the extraction yield to validate the technical viability and better understand the process. Based on the OEC and kinetic parameters calculated using the data from defatting annatto seeds using the SFE bench-scale system, the extraction conditions were selected.

Run A was performed according to the initial state of the pilot-scale unit, i.e., without any changes being made to the equipment. Thus, this extraction process served to allow data such as CO2 consumption (approximately 13 kg) to be surveyed under the processing conditions. In addition, Run A was performed to better compare the effects of the inclusion of the adsorption column and Lung Tank (LT) in assisting CO2 recycling. Runs B and C correspond to the tests in which silicon dioxide (Celite® 512 medium) was used as an adsorbent material. Runs D and E correspond to the tests where the cotton (in a uniform orthopedic blanket roll) was used as an adsorbent material.

Table 3 shows the results for extraction yield and residual extract indicators when S/F was varied. It should be observed here that the extraction yield differs from the global extraction yield (X0) previously obtained in the bench-scale unit since the latter represents the maximum amount of extract that can be recovered from a raw material at a given extraction pressure and temperature (2.82% for annatto seeds for SFE at 313 K and 20 MPa). As observed for the bench-scale unit experiments, the values obtained related to the extract collected during the cleaning of the unit (residual extract amount) were strongly correlated to the S/F ratio. The higher the S/F ratio is, the higher is the extraction yield measured by collecting the extracts in the 3 separation vessels and the lower is the accumulation of extract inside the parts of the SFE pilot-scale unit. Comparing the percentages of residual extract obtained in the pilot-scale unit during runs A-E (7.58-16.65%) with those obtained previously in the bench-scale unit (4.05-8.23%), it can be observed that the pilot-scale unit retains more extract in its tubing (7.58-16.65%). Therefore, any gain related to an increase in the amount of extract collected would be interesting. Therefore, the use of cotton as an adsorbent material for increasing extract recovery in addition to allowing CO2 recycling is a critical issue to be addressed.

In this context, we can see that an increase of 3.8 and 1.6% in the extraction yield was obtained using cotton inside the online subcritical adsorption-based device in runs D and E, respectively. In terms of the adsorbed extract amount (in grams) divided by 100 g of cotton, equivalent values of 1.02% and 0.67% were obtained, indicating that the amount of annatto-seed oil in the final adsorbent material is approximately 1% (see Fig. 7d , the colored cotton material with extract). Considering that in Run E, the S/F ratio was approximately double the value applied in Run D, we can infer that similarly to what occurred with the residual extract deposited in the tubing lines in both units tested here, the use of a higher S/F ratio is also preferred for reducing extract accumulation inside the adsorption column. In our case, when the S/F ratio was increased by 119.61%, the amount of adsorbed extract was reduced by 34.31%. Table 3 also shows the improvement in terms of the lower retention and accumulation of extracts obtained by the inclusion of Teflon bushings in the unit, comparing runs A, B and C (without unit adjustments) with runs D and E (with Teflon bushings and coupled with the developed online subcritical adsorption-based device.

, the colored cotton material with extract). Considering that in Run E, the S/F ratio was approximately double the value applied in Run D, we can infer that similarly to what occurred with the residual extract deposited in the tubing lines in both units tested here, the use of a higher S/F ratio is also preferred for reducing extract accumulation inside the adsorption column. In our case, when the S/F ratio was increased by 119.61%, the amount of adsorbed extract was reduced by 34.31%. Table 3 also shows the improvement in terms of the lower retention and accumulation of extracts obtained by the inclusion of Teflon bushings in the unit, comparing runs A, B and C (without unit adjustments) with runs D and E (with Teflon bushings and coupled with the developed online subcritical adsorption-based device.

Del Valle et al. [33Del Valle JM, Rivera O, Mattea M, Ruetsch L, Daghero J, Flores A. Supercritical CO2 processing of pretreated rosehip seeds: effect of process scale on oil extraction kinetics. J Supercrit Fluids 2004; 31(2): 159-74.

[http://dx.doi.org/10.1016/j.supflu.2003.11.005] ] mentioned that one of the reasons for a low extraction yield compared with that obtained on an analytical (or laboratory) scale is the dispersion of the material extracted between the extraction column and the

separators. Corroborating these findings, in this study, we found that 92.54% and 94.37% of the total residual extract was provided by the separation-vessel cleaning step in runs B and C, respectively.

About the possibility of channeling in this study, it should be noted that the apparent density of the raw materials inside the extractor was the same for the whole runs, 0.7 g/cm3. According to the reference 33Del Valle JM, Rivera O, Mattea M, Ruetsch L, Daghero J, Flores A. Supercritical CO2 processing of pretreated rosehip seeds: effect of process scale on oil extraction kinetics. J Supercrit Fluids 2004; 31(2): 159-74.

[http://dx.doi.org/10.1016/j.supflu.2003.11.005] , the possibility of channeling is higher for a bed with height per diameter ratio of unity, which is far away from height per diameter ratio of 2.4 to 5.8 in the current study. Homogeneous color of the raw material at the end of the extraction is another reason that CO2 distributed homogeneously inside the bed and channeling problem did not occur.

Table 3 shows that increasing S/F improves the extraction yield (g extract/ 100 g annatto seeds) due to higher CO2 consumption. This table also reports the adsorbed mass of extract that is 1 g, for Run B with S/F of 25.45, and 0.66 g, for Run C with S/F of 55.98. One probable reason for lower amount of adsorbed mass of extract of Run C compared to run B is the higher amount of S/F in Run C that carries out higher amount of the extract available in the adsorption column. Accordingly, the total extraction yield, which includes the mass of extract inside the separators and the mass of extract in the adsorption column, determined to be 1.42, for Run A, 1.89, for Run B, and 2.46, for Run C. Moreover, as shown in the last column of this table, an increment of S/F from 3.69 to 55.98 reduces the amount of extract in the lines from 16.65% to 7.58%. This is mainly due to the employing adsorption-base device together with Teflon bushings in the separators that leads to recovering higher amount of extract and reducing the amount of extract in the lines.

3.4. Estimated Cost of the Constructed Online Subcritical Adsorption-based Device

Considering the need to perform tests in the pilot-scale unit to verify the possibility of recirculating CO2 with the least amount of drag on the extract and without requiring a great initial investment, some components were borrowed from other units: a column that was used as adsorption column, a manometer and a micrometering valve (Fig. 9 ). Then, corrective maintenance of 4 valves that were previously in disuse was performed; these valves appear with a (*) in Table 4. In this sense, disregarding the cost calculation of items with (*), we can say that an initial investment of only USD 461.36 was necessary.

). Then, corrective maintenance of 4 valves that were previously in disuse was performed; these valves appear with a (*) in Table 4. In this sense, disregarding the cost calculation of items with (*), we can say that an initial investment of only USD 461.36 was necessary.

|

Fig. (9) Components of the homemade online subcritical adsorption-based device developed to allow effective CO2 recycling. |

On the other hand, an estimated total cost of USD 5731.36 would be required to build the developed device in an SFE unit like the one used here.

CONCLUSION & FUTURE DEVELOPMENTS

The information obtained from the data used to construct the overall extraction curve (OEC) in the SFE bench-scale unit was of great use since it enabled a decision regarding the choice of the extraction time used in the pilot-scale unit for technical validation of the online subcritical adsorption-based device for assisting CO2 recycling. The validation criterion adopted, in addition to visual observation of the adsorbent material after the SFE process, consisted of monitoring the effects of the increase in the solvent mass to feed mass (S/F) ratio on the extraction yield and percentage of residual extract in the equipment parts and comparing the results for the SFE pilot-scale unit coupled with the online subcritical adsorption-based device with the results obtained for the SFE bench-scale unit. In general, the higher the S/F ratio was, the higher was the extraction yield measured and the lower was the accumulation of extract inside the parts of the SFE unit used. Comparing the percentage of residual extract obtained in the pilot-scale unit during runs A-E (6.55-16.65%) with those obtained previously in the bench-scale unit (4.05-8.23%), it can be observed that the pilot-scale unit retained more extract in its tubing (6.55-16.65%).

The amount of extract in each of the parts of the SFE pilot-scale unit reported during the mass balance allowed the recognition of the loss of extract material caused by the existence of empty spaces between connections. This form of loss caused the accumulation of residual extract during the extraction process, and in addition to resulting in low extraction yields, led to a higher consumption of solvents, energy and working hours during the cleaning of the equipment. In this sense, the detailed observation of the connections and various equipment parts suggested the use of an inert material (such as Teflon bushing) to fill these spaces.

The incorporation of an adsorption column along with valves and accessories allowed preliminary tests to be carried out to validate the reincorporation of the CO2 recirculation system in the pilot-scale unit. The tests consisted of defatting annatto seeds, reaching S/F values of 25 and 55 with a mass flow rate of 200 g/min in all cases. This approach achieved the reasonable use of economic resources while at the same time achieving a major saving regarding the purchase of solvent. We could infer that similarl to what occurred with the residual extract deposited in the tubing line in both units tested here, the use of a higher S/F ratio is also preferred for reducing extract accumulation inside the adsorption column.

The cost survey showed that it would cost an estimated total of USD 5731.36 to install the developed device in an SFE unit like the one coupled here (5 L).

Since the proposed device was successfully technically validated using cotton as an adsorbent material, future developments will include the performance of the pseudocontinuous SFE of target compounds using supercritical CO2 in the pilot-scale unit used in this study. Pseudocontinuous SFE is recommended because using n (n ≥ 2) extractor vessels, an industrial plant enables a pseudocontinuous operation to be simulated by intercalating the charge/extraction/discharge steps of each vessel.

Furthermore, the use of other adsorbent materials that in addition to allowing CO2 recycling, can be further used directly as an adsorbent material enriched in bioactive compounds will be studied. For the case of cotton, the colored material (cotton with extract) is applicable in an extremely limited range of applications, and thus this material is unlikely to be pursued in the following steps.

ETHICS APPROVAL AND CONSENT TO PARTICIPATE

Not applicable.

HUMAN AND ANIMAL RIGHTS

No Animals/Humans were used for studies that are basis of this research.

CONSENT FOR PUBLICATION

Not applicable.

CONFLICT OF INTEREST

The authors declares no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENTS

This article was presented orally in the Brazilian Congress on Food Science and Technology - CBCTA 2018 (http://cbcta2018.com.br/). It received the Leopold Hartman Award as the best work among the 1000 works presented in this meeting. R. Abel C. Torres thanks Capes for their doctorate assistantship. Diego T. Santos thanks CNPq (processes 401109/2017-8 and 150745/2017-6) for the postdoctoral fellowship. M. Angela A. Meireles thanks CNPq for the productivity grant (302423/2015-0). The authors acknowledge the financial support from FAPESP (process 2015/13299-0).

REFERENCES

| [1] | Martin A, Mattea F, Gutierrez L, Miguel F, Cocero MJ. Co-precipitation of carotenoids and bio-polymers with the supercritical anti-solvent process. J Supercrit Fluids 2007; 41(1): 138-47. [http://dx.doi.org/10.1016/j.supflu.2006.08.009] |

| [2] | Tocchini L, Mercadante AZ. Extração e determinação, por clae, de bixina e norbixina em coloríficos. Food Sci Technol (Campinas) 2001; 21: 310-3. [http://dx.doi.org/10.1590/S0101-20612001000300010] |

| [3] | Stahl W, Sies H. Antioxidant activity of carotenoids. Mol Aspects Med 2003; 24(6): 345-51. [http://dx.doi.org/10.1016/S0098-2997(03)00030-X] [PMID: 14585305] |

| [4] | Santos DT, Albarelli JQ, Beppu MM, Meireles MAA. Stabilization of anthocyanin extract from jabuticaba skins by encapsulation using supercritical CO2 as solvent. Food Res Int 2013; 50(2): 617-24. [http://dx.doi.org/10.1016/j.foodres.2011.04.019] |

| [5] | Shahid M, Shahid UI, Mohammad F. Recent advancements in natural dye applications: a review. J Clean Prod 2013; 53: 310-31. [http://dx.doi.org/10.1016/j.jclepro.2013.03.031] |

| [6] | Tapiero H, Townsend DM, Tew KD. The role of carotenoids in the prevention of human pathologies. Biomed Pharmacother 2004; 58(2): 100-10. [http://dx.doi.org/10.1016/j.biopha.2003.12.006] [PMID: 14992791] |

| [7] | Rodrigues SM, Soares VLF, de Oliveira TM, Gesteira AS, Otoni WC, Costa MGC. Isolation and purification of RNA from tissues rich in polyphenols, polysaccharides, and pigments of annatto (Bixa orellana L.). Mol Biotechnol 2007; 37(3): 220-4. [http://dx.doi.org/10.1007/s12033-007-0070-9] [PMID: 17952668] |

| [8] | Rosa MTMG, Silva EK, Santos DT, Petenate AJ, Meireles MAA. Obtaining annatto seed oil miniemulsions by ultrasonication using aqueous extract from Brazilian ginseng roots as a biosurfactant. J Food Eng 2016; 168: 68-78. [http://dx.doi.org/10.1016/j.jfoodeng.2015.07.024] |

| [9] | van Scheppingen WB, Boogers IALA, Duchateau ALL. Study on decomposition products of norbixin during bleaching with hydrogen peroxide and a peroxidase by means of UPLC-UV and mass spectrometry. Food Chem 2012; 132(3): 1354-9. [http://dx.doi.org/10.1016/j.foodchem.2011.11.118] [PMID: 29243622] |

| [10] | Barrozo MAS, Santos KG, Cunha FG. Mechanical extraction of natural dye extract from Bixa orellana seeds in spouted bed. Ind Crops Prod 2013; 45: 279-82. [http://dx.doi.org/10.1016/j.indcrop.2012.12.052] |

| [11] | Albuquerque CLC, Meireles MAA. Defatting of annatto seeds using supercritical carbon dioxide as a pretreatment for the production of bixin: Experimental, modeling and economic evaluation of the process. J Supercrit Fluids 2012; 66: 86-95. [http://dx.doi.org/10.1016/j.supflu.2012.01.004] |

| [12] | Moraes MN, Zabot GL, Meireles MAA. Applications of supercritical fluids in latin america: Past, present and future trends. Food Public Health 2014; 4(3): 162-79. [http://dx.doi.org/10.5923/j.fph.20140403.11] |

| [13] | Johner JCF, Meireles MAA. Construction of a supercritical fluid extraction (SFE) equipment: validation using annatto and fennel and extract analysis by thin layer chromatography coupled to image. Food Sci Technol (Campinas) 2016; 36(2): 210-47. [http://dx.doi.org/10.1590/1678-457X.0027] |

| [14] | Rodrigues LM, Alcázar-Alay SC, Petenate AJ, Meireles MAA. Bixin extraction from defatted annatto seeds. C R Chim 2014; 17(3): 268-83. [http://dx.doi.org/10.1016/j.crci.2013.10.010] |

| [15] | Mattea F, Martín Á, Matías-Gago A, Cocero MJ. Supercritical antisolvent precipitation from an emulsion: β-Carotene nanoparticle formation. J Supercrit Fluids 2009; 51(2): 238-47. [http://dx.doi.org/10.1016/j.supflu.2009.08.013] |

| [16] | Santos DT, Meireles MAA. Micronization and encapsulation of functional pigments using supercritical carbon dioxide. J Food Process Eng 2013; 36(1): 36-49. [http://dx.doi.org/10.1111/j.1745-4530.2011.00651.x] |

| [17] | Nong D, Siriwardana M. Environmental and economic impacts of a joint emissions trading scheme. Int J Glob Energy Issues 2017; 40(3-4): 184-206. [http://dx.doi.org/10.1504/IJGEI.2017.086619] |

| [18] | Royer-Adnot J, Le Gallo Y. Economic analysis of combined geothermal and CO2 storage for small-size emitters. Energy Procedia 2017; 114: 7118-25. [http://dx.doi.org/10.1016/j.egypro.2017.03.1853] |

| [19] | Silva GF, Gamarra FMC, Oliveira AL, Cabral FA. Extraction of bixin from annatto seeds using supercritical carbon dioxide. Braz J Chem Eng 2008; 25: 419-26. [http://dx.doi.org/10.1590/S0104-66322008000200019] |

| [20] | AOAC. Official Methods of Analysis of AOAC International 1997. |

| [21] | NIST. National Institute of Standards and Technology. 2017. Available at: http://www.nist.gov |

| [22] | Zabot GL, Moraes MN, Petenate AJ, Meireles MAA. Influence of the bed geometry on the kinetics of the extraction of clove bud oil with supercritical CO2. J Supercrit Fluids 2014; 93: 56-66. [http://dx.doi.org/10.1016/j.supflu.2013.10.001] |

| [23] | Prado JM. Estudo do aumento de escala do processo de extração supercrítica em leito fixo. Ph.D thesis, University of Campinas/School of Food Engineering, Campinas, Brazil, 2010. |

| [24] | Jesus SP, Calheiros MN, Hense H, Meireles MAA. A simplified model to describe the kinetic behavior of supercritical fluid extraction from a rice bran oil byproduct. Food Public Health 2013; 3: 215-22. [http://dx.doi.org/10.5923/j.fph.20130304.05] |

| [25] | Meireles MAA. Extraction of bioactive compounds from latim american plants.Supercritical Fluid Extraction of Nutraceuticals and Bioactive Compounds: CRC Press - Taylor & Francis Group, LLC 2008; 243-74. |

| [26] | Moraes MN, Zabot GL, Meireles MAA. Extraction of tocotrienols from annatto seeds by a pseudo continuously operated SFE process integrated with low-pressure solvent extraction for bixin production. J Supercrit Fluids 2015; 96: 262-71. [http://dx.doi.org/10.1016/j.supflu.2014.09.007] |

| [27] | Takeuchi TM, Leal PF, Favareto R, et al. Study of the phase equilibrium formed inside the flash tank used at the separation step of a supercritical fluid extraction unit. J Supercrit Fluids 2008; 43(3): 447-59. [http://dx.doi.org/10.1016/j.supflu.2007.08.002] |

| [28] | EXERGY-LLC. Model # 00256-06, Shell & Tube Heat Exchanger. USA, 17/05/2017 2017. Available at: http://heat-exchangers. exergyllc.com/item/shell-tube-heat-exchangers/35-series-shell-tube-heat- exchangers/ 00256-06 |

| [29] | POLYSCIENCE. Chillers and Coolers. USA, 2017. Available at: https://polyscience.com/products/chillers/benchtop |

| [30] | POLYSCIENCE. User Guide - Refrigerated Recirculating Chillers 2016; 51. |

| [31] | Santos DT, Albuquerque CLC, Meireles MAA. Procedia Food Sci 2011; 1: 1581-8. [http://dx.doi.org/10.1016/j.profoo.2011.09.234] |

| [32] | Torres RADC. Purificação de partículas de bixina por precipitação com CO2 supercrítico como antissolvente a partir de solução de ativos obtida da extração de sementes semi desengorduradas de urucum (Bixa orellana L.) assistida por ultrassom. Master thesis, University of Campinas/School of Food Engineering, Campinas, Brazil, 2015. |

| [33] | Del Valle JM, Rivera O, Mattea M, Ruetsch L, Daghero J, Flores A. Supercritical CO2 processing of pretreated rosehip seeds: effect of process scale on oil extraction kinetics. J Supercrit Fluids 2004; 31(2): 159-74. [http://dx.doi.org/10.1016/j.supflu.2003.11.005] |